Features

REXPEARL™ EEA

Resistant to both “heat” and “ice”

Standard soft polyolefins that can be used in various environments

- Applicable for various fillers

- Good coolness resistance

- Flexible

High heat resistance - For modification

REXPEARL™ EMA

"Flexible, easy-to-use low-melting polyolefin

made with methyl acrylate x ethylene"

- Flexible

- Good thermal decomposition resistance

- Suitable for High-frequency welding

- Low Melting Point

- Silk-Like Smoothness

REXPEARL™ ET

New innovations in multi-materialization

Highly functional materials that expand design possibilities through the power of chemistry

- Adhesive

- Compatible

- Dispersible

- Soluble to Solvents

- Flexible

- For Reactive Processing

REXPEARL™ FR

"Design free non-halogen flame-retardant polyethylene

For your safe and clean everyday life"

- Flame Resistance

- Low Smoke

- Nontoxic

- Processable

- Colorable

- Customizable

Application

Modifying Plastic

- EEA

- EMA

- ET

- FR

Modifying Asphalt

- EEA

- EMA

- ET

- FR

Films

- EEA

- EMA

- ET

- FR

Compatibilizer

- EEA

- EMA

- ET

- FR

Resin Adhesive

- EEA

- EMA

- ET

- FR

Hot-melt Adhesive

- EEA

- EMA

- ET

- FR

Binder Powder

- EEA

- EMA

- ET

- FR

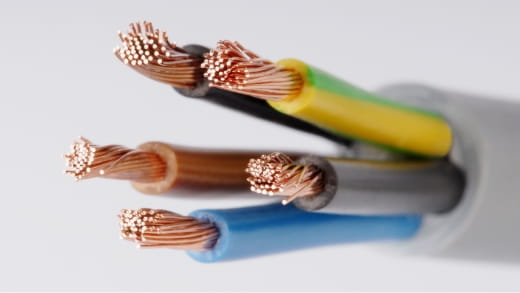

Wire Coating

- EEA

- EMA

- ET

- FR

Cable Coating

- EEA

- EMA

- ET

- FR

Wall Paper (Assumed)

- EEA

- EMA

- ET

- FR

Flooring (Assumed)

- EEA

- EMA

- ET

- FR

Line up / Download

Physical properties REXPEARL™

| Basic Properties | Unit | Method | A1100 | A3100 | A1150 | A4200 | A6200 | A4250 |

|---|---|---|---|---|---|---|---|---|

| MFR | g/10min | ISO 1872-2 | 0.4 | 3 | 0.8 | 5 | 20 | 5 |

| Density | g/cm3 | ISO 1872-1,2 | 0.930 | 0.930 | 0.932 | 0.934 | 0.934 | 0.937 |

| Ethyl Acrylate Content | wt% | JPE Method | 10 | 10 | 15 | 20 | 20 | 25 |

| Tensile Modulus | MPa | ISO 527-2 | 90 | 80 | 46 | 23 | 18 | - |

| Tensile Strength at Yield | MPa | ISO 1872-2 | No-Yield | No-Yield | No-Yield | No-Yield | No-Yield | No-Yield |

| Tensile Strength at Break | MPa | ISO 1872-2 | No-Break | No-Break | No-Break | No-Break | No-Break | No-Break |

| Tensile Strain at Break | % | ISO 1872-2 | >400 | >400 | >400 | >400 | >400 | >400 |

| Tensile Modulus | MPa | ISO 1872-2 | 99 | 93 | 54 | 28 | 22 | 21 |

| Charpy Impact Strength | kJ/m2 | ISO 1872-2 | No-Break | No-Break | No-Break | No-Break | No-Break | No-Break |

| Tensile Impact Strength | kJ/m2 | ISO 1872-2 | 290 | 250 | 250 | 280 | 230 | 290 |

| Durometer Hardness, Type D |

- | ISO 868 | 46 | 44 | 41 | 34 | 31 | 30 |

| Vicat Softening Temperature | ℃ | ISO 306 | 83 | 75 | 67 | 50 | 43 | 41 |

| Melting Point | ℃ | ISO 11357-3 | 104 | 104 | 100 | 96 | 94 | 92 |

| Brittleness Temperature | ℃ | ISO 974 | <-70 | <-70 | <-70 | <-70 | <-70 | <-70 |

| Test Specimens | Compression | Compression | Compression | Compression | Compression | Compression | ||

| Application |

|

|

|

|

|

|

||

| PL confirmation certificate for food applications (JPN) | Approved | Approved | Approved | Unapproved | Unapproved | Unapproved | ||

| Basic Properties | Unit | Method | EB330H | EB230X | EB140F | EB240H | EB440H | EB050S | EB033FC |

|---|---|---|---|---|---|---|---|---|---|

| MFR | g/10min | ISO 1872-2 | 10 | 6.0 | 2.6 | 6.0 | 20 | 2.0 | 2.0 |

| Density | g/cm3 | ISO 1872-1,2 | 0.931 | 0.935 | 0.941 | 0.941 | 0.941 | 0.947 | 0.937 |

| Methyl Acrylate Content | wt% | JPE Method | 12 | 14 | 20 | 20 | 20 | 24 | 15 |

| Tensile Modulus | MPa | ISO 1872-2 | 51 | 42 | 23 | 23 | 22 | 15 | 42 |

| Tensile Strength at Yield | MPa | ISO 1872-2 | No-Yield | No-Yield | No-Yield | No-Yield | No-Yield | No-Yield | No-Yield |

| Tensile Strength at Break | MPa | ISO 1872-2 | No-Break | No-Break | No-Break | No-Break | No-Break | No-Break | No-Break |

| Tensile Strain at Break | % | ISO 1872-2 | >400 | >400 | >400 | >400 | >400 | >400 | >400 |

| Flexural Modulus | MPa | ISO 1872-2 | 55 | 47 | 25 | 25 | 22 | 19 | 48 |

| Charpy Impact Strength | kJ/m2 | ISO 1872-2 | No-Break | No-Break | No-Break | No-Break | No-Break | No-Break | No-Break |

| Tensile Impact Strength | kJ/m2 | ISO 1872-2 | 180 | 190 | 230 | 230 | 220 | 300 | 220 |

| Durometer Hardness, Type D |

- | ISO 868 | 41 | 37 | 32 | 32 | 29 | 30 | 36 |

| Durometer Hardness, Type A |

- | ISO 868 | 91 | 89 | 84 | 84 | 84 | 82 | 90 |

| Vicat Softening Temperature | ℃ | ISO 306 | 61 | 58 | 47 | 47 | 44 | 42 | 49 |

| Melting Point | ℃ | ISO 11357-3 | 90 | 87 | 77 | 77 | 77 | 73 | |

| Brittleness Temperature | ℃ | ISO 974 | <-70 | <-70 | <-70 | <-70 | <-70 | <-70 | <-70 |

| Test Specimens | Compression | Compression | Compression | Compression | Compression | Compression | Compression | ||

| Application |

|

|

|

|

|

|

|

||

| PL confirmation certificate for food applications (JPN) | Approved | Approved | Approved | Approved | Approved | Approved | Approved | ||

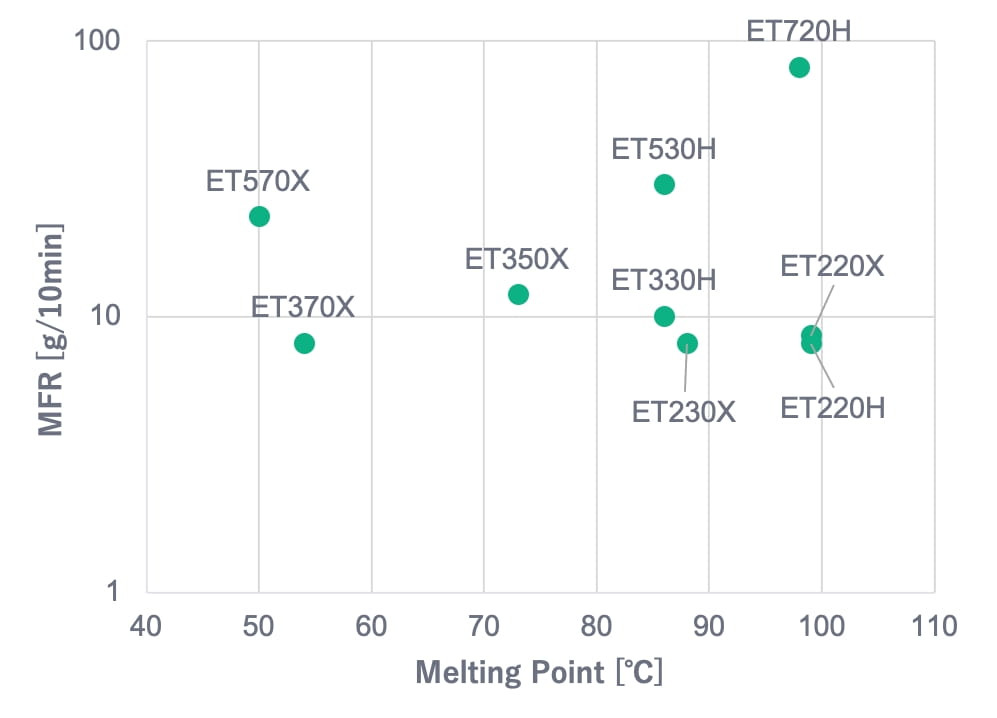

| Basic Properties | Unit | Method | ET220X | ET220H | ET230X | ET330H | ET350X | ET530H | ET720X | Under Development |

Under Development |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MFR | g/10min | ISO 1872-2 | 8.5 | 8.0 | 8.0 | 10 | 12 | 30 | 80 | 8 | 23 |

| Density | g/cm3 | ISO 1872-1,2 | 0.939 | 0.940 | 0.938 | 0.946 | 0.951 | 0.948 | 0.939 | 0.96 | 0.964 |

| Methyl Acrylate Content | wt% | JPE Method | 8 | 8 | 12 | 16 | 23 | 16 | 8 | 33 | 33 |

| Maleic Anhydride Conten | wt% | JPE Method | Medium | Medium | Low | Medium | Medium | High | Medium | Medium | Medium |

| Flexural Modulus | MPa | ISO 1872-2 | 100 | 100.000 | 57.000 | 39 | 21 | 36 | 89 | 5 | 5 |

| Tensile Strength at Yield | MPa | ISO 1872-2 | No-Yield | No-Yield | No-Yield | No-Yield | No-Yield | No-Yield | No-Yield | No-Yield | No-Yield |

| Tensile Strength at Break | MPa | ISO 1872-2 | No-Break | No-Break | No-Break | No-Break | No-Break | No-Break | No-Break | No-Break | No-Break |

| Tensile Strain at Break | % | ISO 1872-2 | >400 | >400 | >400 | >400 | >400 | >400 | >400 | >400 | >400 |

| Charpy Impact Strength | kJ/m2 | ISO 1872-2 | No-Break | No-Break | No-Break | No-Break | No-Break | No-Break | No-Break | No-Break | No-Break |

| Tensile Impact Strength | kJ/m2 | ISO 1872-2 | 180 | 180 | 210 | 210 | 470 | 180 | 140 | 230 | 210 |

| Tensile Modulus | MPa | ISO 1872-2 | 97 | 97 | 54 | 39 | 19 | 37 | 77 | 10 | 10 |

| Durometer Hardness, Type D |

- | ISO 868 | 45 | 45 | 39 | 37 | 31 | 36 | 44 | 14 | 10 |

| Durometer Hardness, Type A |

- | ISO 868 | - | - | - | - | 79 | - | - | 52 | 59 |

| Vicat Softening Temperature | ℃ | JIS K7206 | 79 | 79 | 64 | 54 | 40 | 51 | 67 | - | - |

| Melting Point | ℃ | ISO 11357-3 | 99 | 99 | 88 | 86 | 73 | 86 | 98 | 86 | 98 |

| Brittleness Temperature | ℃ | ISO 974 | <-70 | <-70 | <-70 | <-70 | <-70 | <-70 | <-70 | <-70 | <-70 |

| Test Specimens | Compression | Compression | Compression | Compression | Compression | Compression | Compression | Compression | Compression | ||

| Application |

|

|

|

|

|

|

|

- | - | ||

| PL confirmation certificate for food applications (JPN) | Approved | Unapproved | Approved | Approved | Approved | Approved | Approved | - | - | ||

| Basic Properties | Unit | Method | CA1153BM | CA1155B | CR138GB | CR236GB | CR230GB | CR238GB | CR272FY | CA11571N | CR246FH | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MFR | g/10min | ISO 1872-2 | 0.27 | 0.12 | 0.14 | 0.13 | 0.17 | 0.10 | 0.22 | 0.08 | 0.38 | |

| Density | g/cm3 | ISO 1872-1,2 | 1.29 | 1.31 | 1.31 | 1.31 | 1.28 | 1.30 | 1.37 | 1.40 | 1.28 | |

| Tensile Strength | MPa | ISO 37 | 15.3 | 14.6 | 13.2 | 13.1 | 14.3 | 14.7 | 14.0 | 15.2 | 15.0 | |

| Tensile Strain at Break | % | ISO 37 | 670 | 640 | 580 | 640 | 630 | 590 | 700 | 690 | 730 | |

| Property at Aging | Aging condition | -- | JIS C 3005 | 100℃ × 48h | 100℃ × 48h | 100℃ × 48h | 100℃ × 48h | 100℃ × 48h | 100℃ × 48h | 100℃ × 48h | 100℃ × 48h | 90℃ × 96h |

| Strength Retention | % | 93 | 96 | 91 | 96 | 90 | 88 | 88 | 95 | 93 | ||

| Strain Retention | % | 101 | 100 | 92 | 101 | 96 | 95 | 99 | 100 | 103 | ||

| Cold Impact | @-50℃ | - | JIS C3005 | NB | NB | NB | NB | NB | NB | (NB@-40℃) | NB | NB |

| ESCR | 50℃ 48h | - | ASTM D1693 | NB | NB | NB | NB | NB | NB | NB | NB | NB |

| Smoke Density(Non Flaming) | Ds | ASTM E 662 | 69 | 73 | 59 | 69 | 57 | 55 | 49 | 50 | 53 | |

| Gas Acidity at Combustion | pH | JCS 7397 | 4.0 | 3.8 | 3.8 | 4.2 | 4.2 | 4.3 | 4.3 | 4.1 | 4.5 | |

| Oxygen Index | O2% | ISO 4589-1 | 37 | 36 | 36 | 33 | 33 | 32 | 32 | 36 | 24 | |

| Color Variations | Catalog | Black | Black | Black | Black | Black | Black | Yellow | Natural | Gray | ||

| Others | Orange | Red, Blue | Please Contact | |||||||||

| Application |

|

|

|

|

|

|

|

|

|

|||

- The information on this document shows typical properties and characteristics only and is intended as guide, not as specifica tions.

- Before using the product herein, the users should make their own determination of the suitability (quality, safety, legal, in tellectual property rights etc.) of such products for the intended use.

- The product on this sheet may be not suitable for pharmaceutical or medical applications. When you use the product for such a pplications, please be sure to have a consultation with us in advance

- about your use.

- Please consult our company about applications in the food-contacting articles or durable goods.

- Please understand that this information provided herein might be changed without a previous notice.

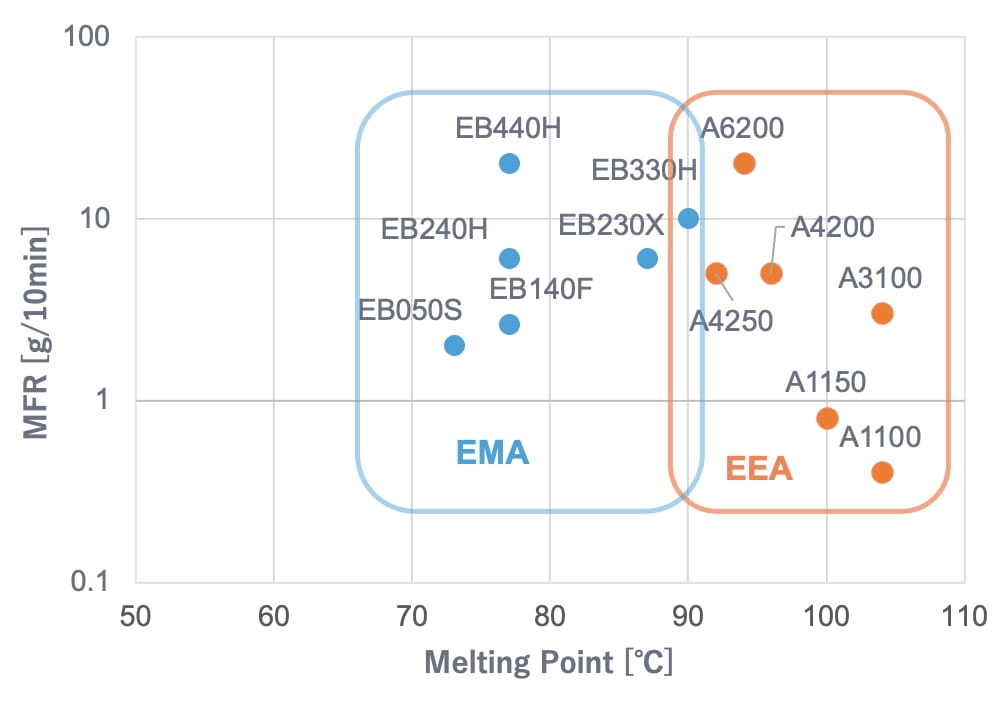

REXPEARL™ EEA、EMA Tm/MFR profile

REXPEARL™ ET Tm/MFR profile