REXPEARL™ ET

Ethylene copolymer copolymerized with methyl acrylate, which enhances flexibility, and maleic anhydride, which imparts reactivity.

The compatibility and reactivity of the two comonomers improve the performance of various materials.

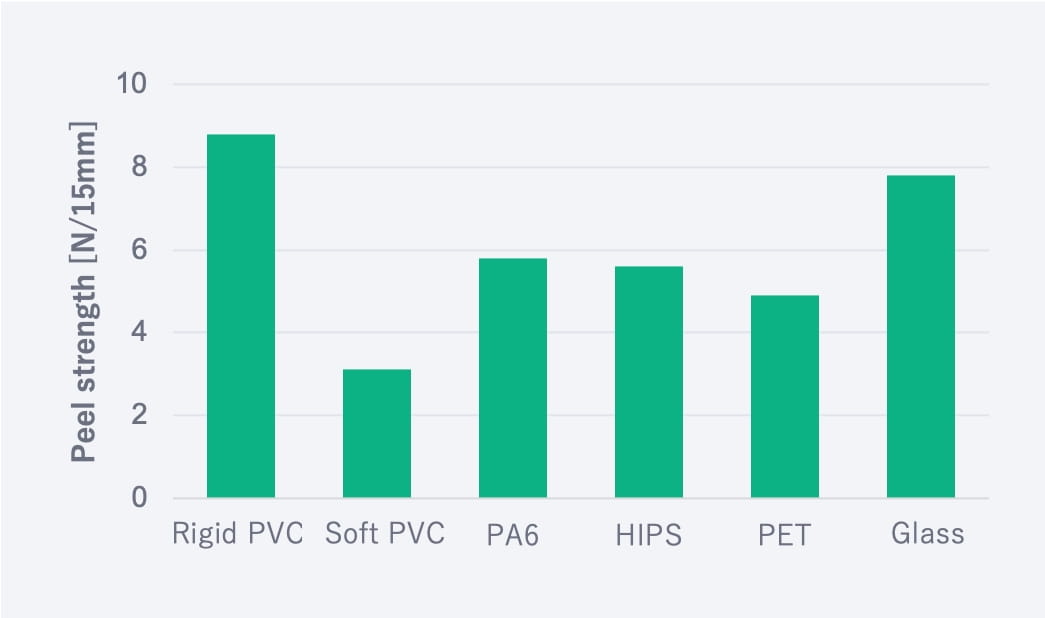

Adhesive

- It can be bonded to various adherends by various lamination methods such as thermocompression bonding, co-extrusion, and lamination.

| Adherend | Thickness of adherend μm |

bonding temperature ℃ |

Peelstrength N/15mm |

|---|---|---|---|

| RigidPVC | 160 | 140 | 8.8 |

| SoftPVC | 100 | 140 | 3.1 |

| PA6 | 15 | 140 | 5.8 |

| HIPS | 1100 | 140 | 5.6 |

| PET | 12 | 140 | 4.9 |

| Glass | 2000 | 180 | 7.8 |

Adhesive strength measurement conditions

Prepared samples for adhesion strength measurement of substrate (12 µm)/Rexpar ET (25 µm)

Bonding method: Thermo-compression bonding Pressure: 0.2 MPa Bonding time: 1 s

Peeling test condition: 180° peeling test Peeling speed: 300mm/sec

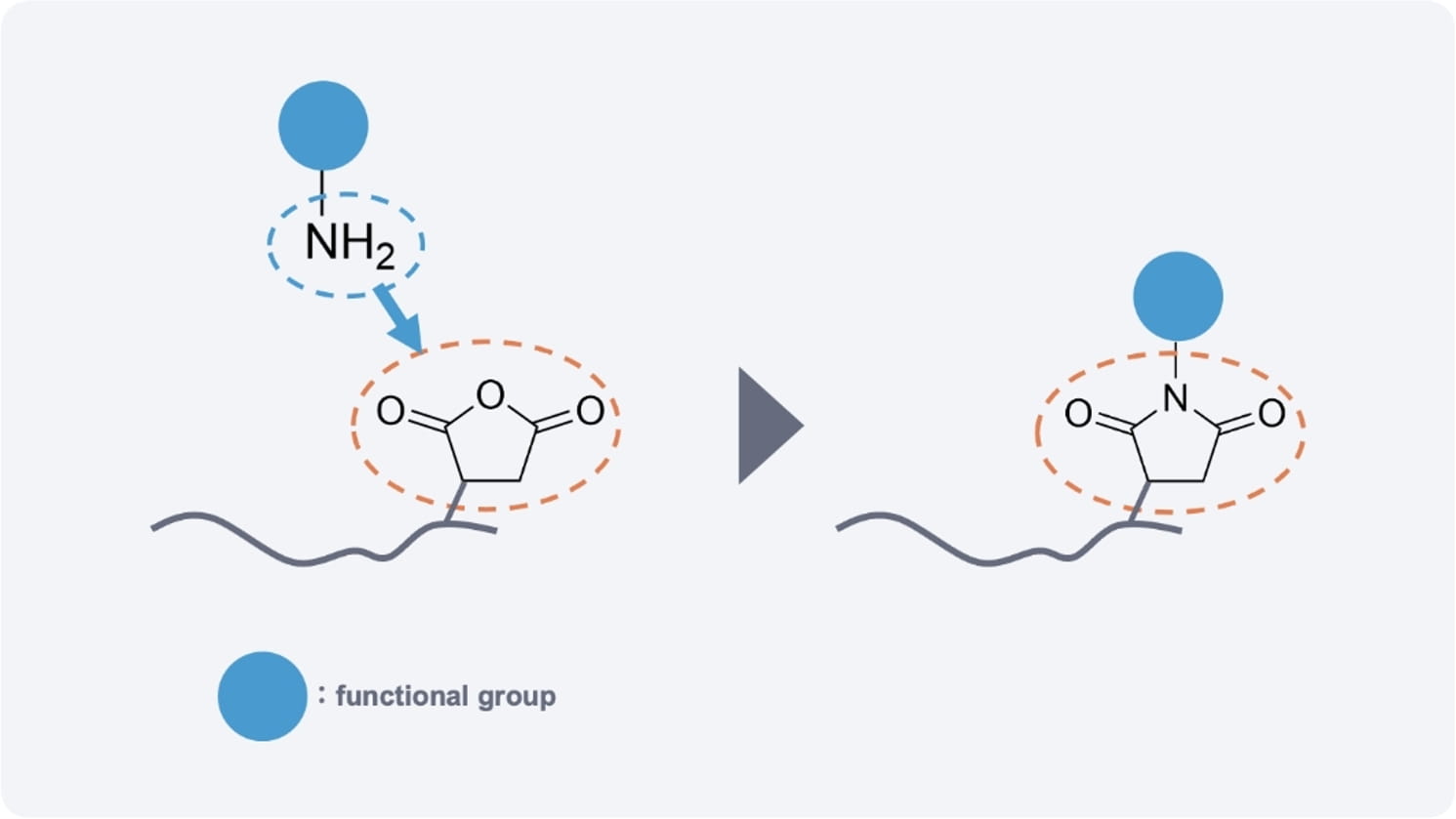

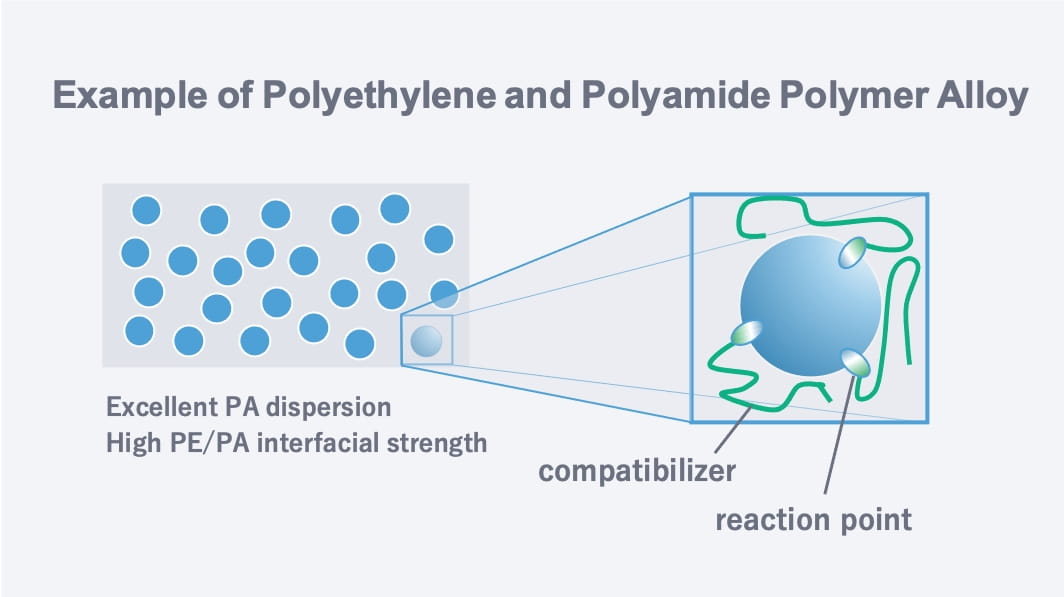

For Reactive Processing

Compatible

- By adding REXPEARL™ ET when blending polyethylene and different materials, you can increase its compatibility. It is more effective if the material is reactive to maleic anhydride.

- Blending dissimilar materials often results in giving negative impacts on transparency and impact resistance, but the use of compatibilizers in combination can reduce these damages.

- Adapting this to material recycling of multi-material items including polyethylene, you can improve the performance of recycled materials.

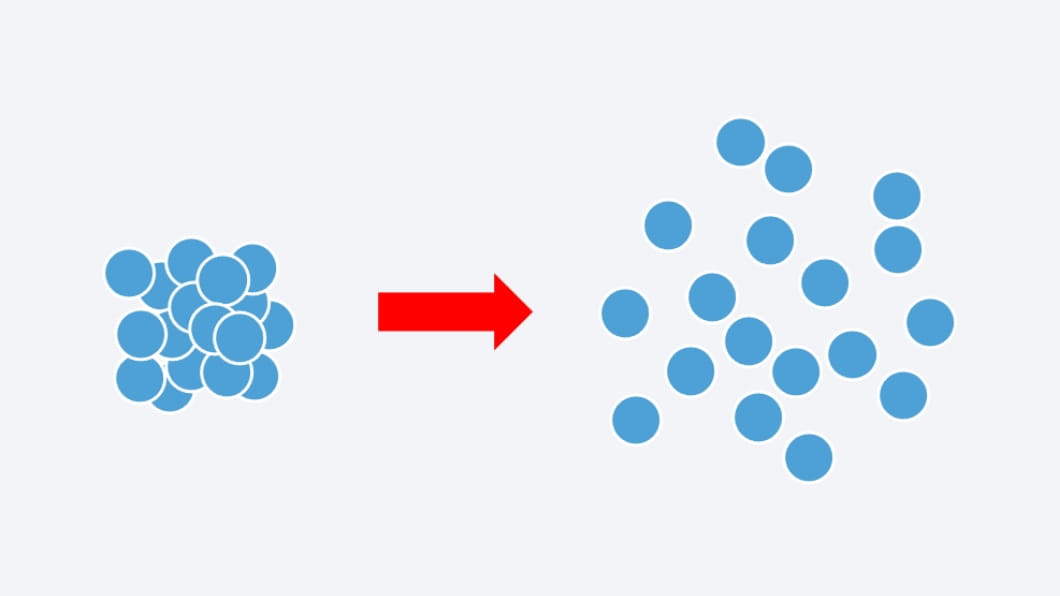

Dispersible

- By adding REXPEARL™ ET when blending fillers to your polyethylene, you can enhance its dispersion.

- Maleic anhydride prevents filler from falling out of the polyethylene matrix, thereby suppressing the reduction of physical properties such as impact resistance that occurs by the addition of the filler.

- It can be used as a dispersing material for various materials such as organic and inorganic fillers that can interact with maleic anhydride.

Soluble to Solvents

- REXPEARL™ ET can be dissolved various solvents such as toluene and xylene.

- The higher the comonomer content is, the higher the solubility becomes, and depending on the combination with the solvent, it can maintain its soluble state even at room temperature.

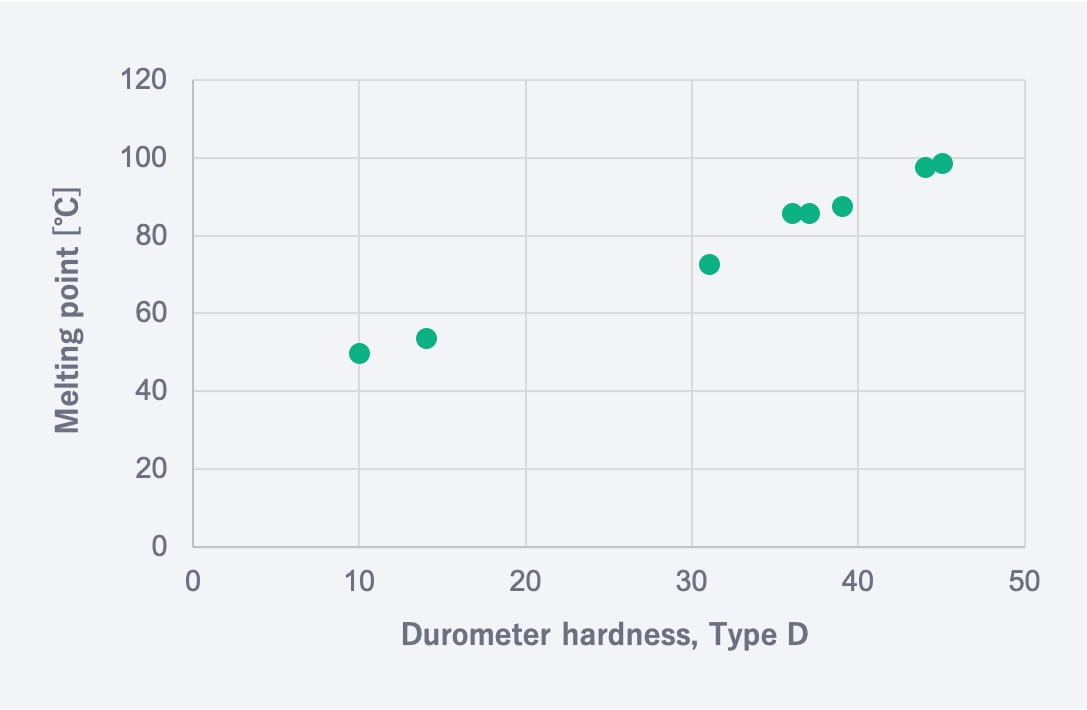

Flexible

- Copolymerization of ethylene and methyl acrylate increases flexibility.

- For more flexible grades, a grade which its Durometer A hardness is "52" is now under development.