Features

By using our unique polymerization technology, our high-density polyethylene produced from Ziegler-Natta catalyst and chromium catalyst will enable you to use our products in various products.

01Suitable for various applications

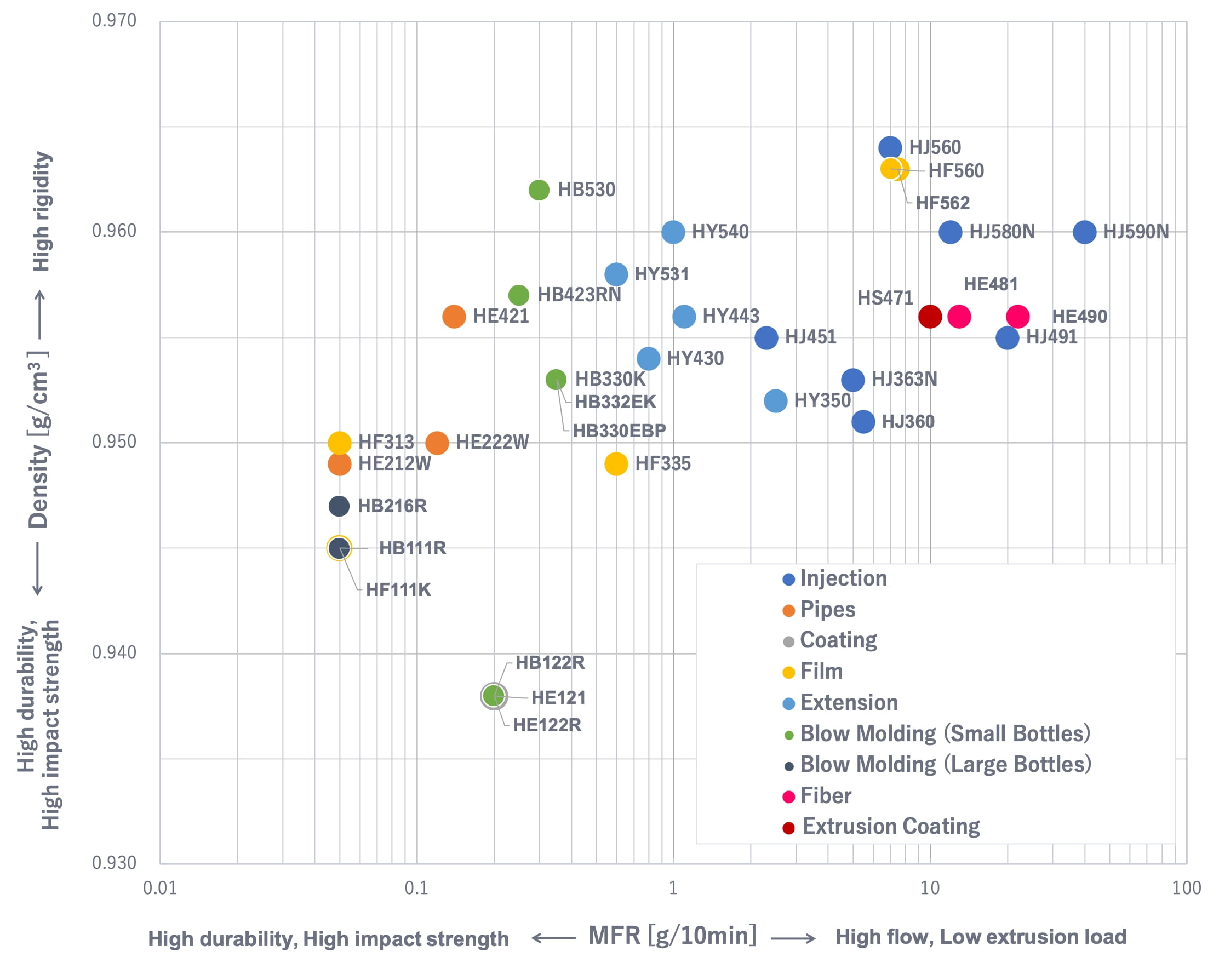

We have a wide lineup of grades with various MFR and densities to meet your molding methods, such as inflation, lamination, injection, extrusion, blow and so on.

02Excellent performance (e.g., melt tension)

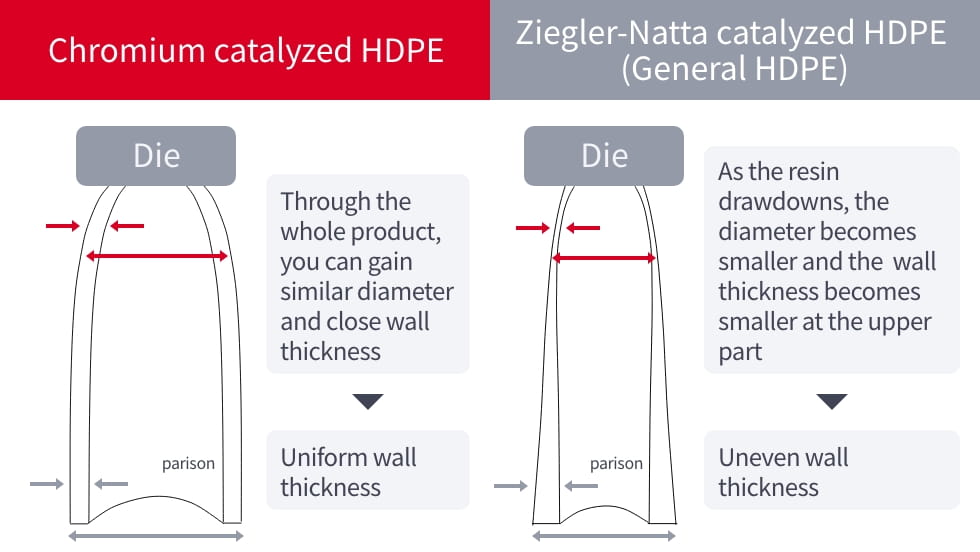

High-density polyethylene for blow molding produced by using our chromium catalyst shows high melt tension, which leads to excellent drawdown resistance and bore concentricity.

03Three production sites

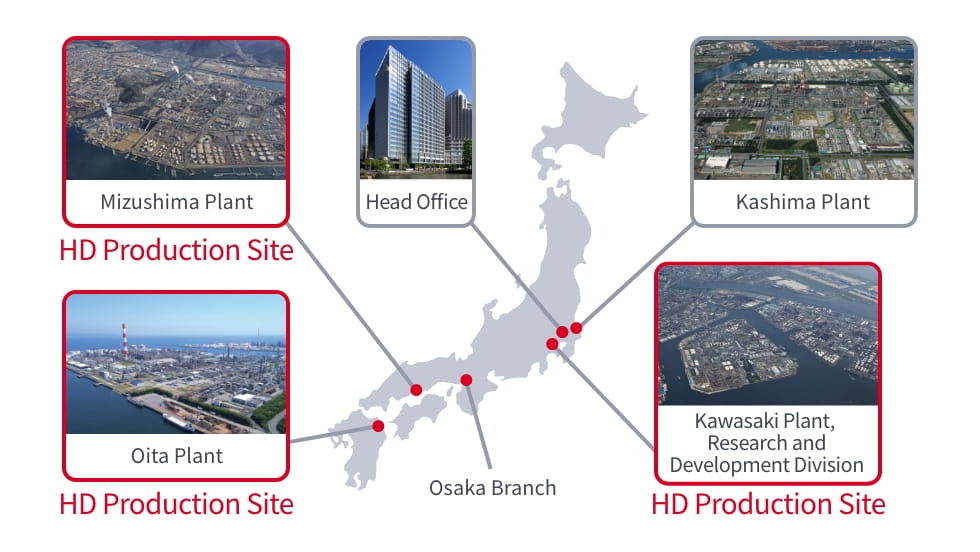

NOVATECTMHD is manufactured at three locations in Japan: Kawasaki, Mizushima, and Oita. Many grades are produced regularly in multiple production sites, and in the case of emergency, not only are we keeping some safety stocks, but we are also preparing a BCP which includes producing some grades in irregular production sites.

04Conformed to various specifications

Look for our grade lineup for grades conformed to the specifications you need: such as PE100 (ISO12162:2009), BMP certification (Japan BioPlastics Association) etc.

05Being used for unique applications

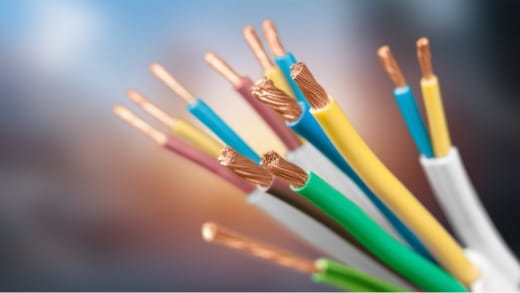

Some of our products are used for unique applications which requires strict quality control: such as safety parts for vehicles, flammable gas equipment and containers, insulated cables for ultra-high voltage, and ultra-high purity cans for engineering chemicals. (In use of these applications, please contact us in advance.)

06Grades with Biomass Plastics

Our blow molding grade HB330EBP is blended with bio-polyethylene made from plant-based ethanol.

It is registered on the Positive List of Japan BioPlastics Association as a polyethylene with 31% biomass plastic content. It is used for detergent bottles.

Application

Film (Inflation, Cast etc.)

Extrusion Lamination

Drink Bottle Caps (Injection Molding)

Bottles and Containers (Blow Molding)

Food Packaging

(Sheets improvement)

Flat yarn, Mono-filament

Fibers

Auto Parts

Pipe

Cables

Line up / Download

Physical properties NOVATEC™ HD

- The information on this document shows typical properties and characteristics only and is intended as guide, not as specifica tions.

- Before using the product herein, the users should make their own determination of the suitability (quality, safety, legal, in tellectual property rights etc.) of such products for the intended use.

- The product on this sheet may be not suitable for pharmaceutical or medical applications. When you use the product for such a pplications, please be sure to have a consultation with us in advance

- about your use.

- Please consult our company about applications in the food-contacting articles or durable goods.

- Please understand that this information provided herein might be changed without a previous notice.

NOVATEC™ HD MFR/density profile