Features

We have a wide variety of grades to meet your various uses and manufacturing methods

Our Unique Grades

01Clean

We have a wide variety of additive-free grades. They are successfully used in many fields where cleanness is required, such as food applications.

Product Examples

LC600A, LC602A

02High Quality

We have specially controlled grades which can reduce the defects in your films. It is widely used for protective films for electronic and optical parts.

Product Examples

LF441A

03Stable BCP

We have multiple production location which will contribute to stabilize your BCP.

※For certain products only. Please contact us for details.

Our Unique Grades

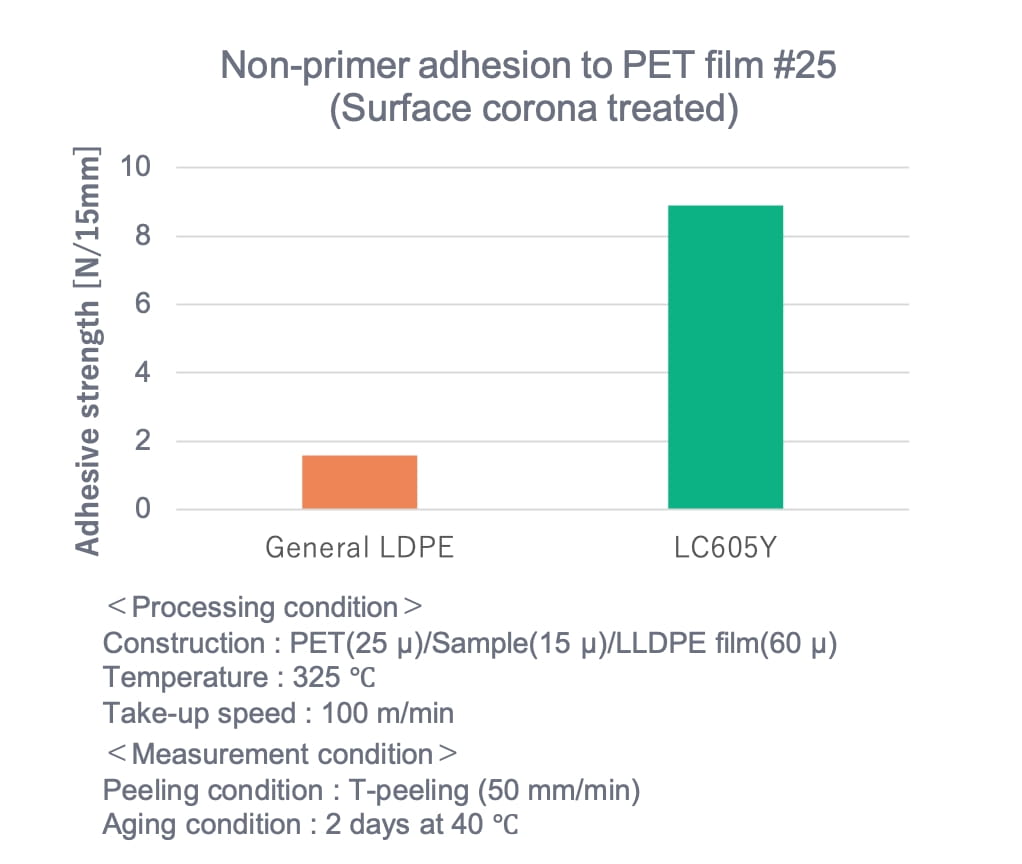

Non-Primer Lamination:

「LC605Y」

LC605Y shows excellent adhesion to the base film in the extrusion laminating process without the use of primer coating agents (adhesives + solvents).

Specialties

- Solvent-Free (Environmentally-Friendly, No need to management solvents)

- Excellent molding processability

- No need for trimming (Reduction of loss)

- No need for using purging materials (Reduction of loss)

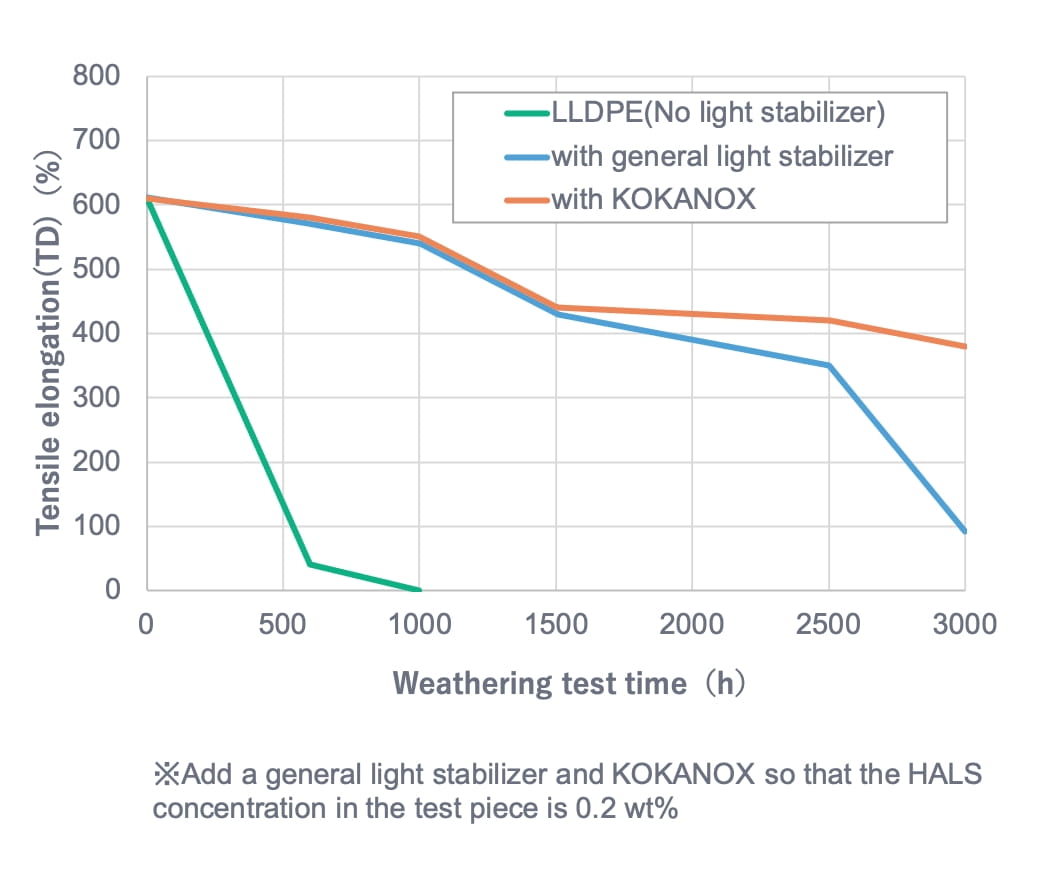

Ultra-High Weather Resistance:

KOKANOX XJ100H

Because XJ100H does not bleed like the conventional blended-type weather agents, even if it is added only for a small scale, it can provide excellent weather resistance (especially suitable for outdoor usages). This grade is widely used for outdoor agricultural materials.

Specialties

- Anti Bleed

- Long-life weather resistance (Especially suitable for outdoor usages)

- Suitable for long-life products

Environmentally-Friendly

We can propose solutions which will meet your needs. Please feel free to ask.

Examples

Reducing plastic usage, Energy-saving, Solvent-free, Plastic recycles etc.

※Please contacts us for further details

Application

NOVATEC LD is used in various fields, from food packages to industrial materials

Food Packages

Drink Boxes

Protection Films

Industrial Materials

Line up / Download

Physical properties NOVATEC™ LD

- The information on this document shows typical properties and characteristics only and is intended as guide, not as specifica tions.

- Before using the product herein, the users should make their own determination of the suitability (quality, safety, legal, in tellectual property rights etc.) of such products for the intended use.

- The product on this sheet may be not suitable for pharmaceutical or medical applications. When you use the product for such a pplications, please be sure to have a consultation with us in advance

- about your use.

- Please consult our company about applications in the food-contacting articles or durable goods.

- Please understand that this information provided herein might be changed without a previous notice.

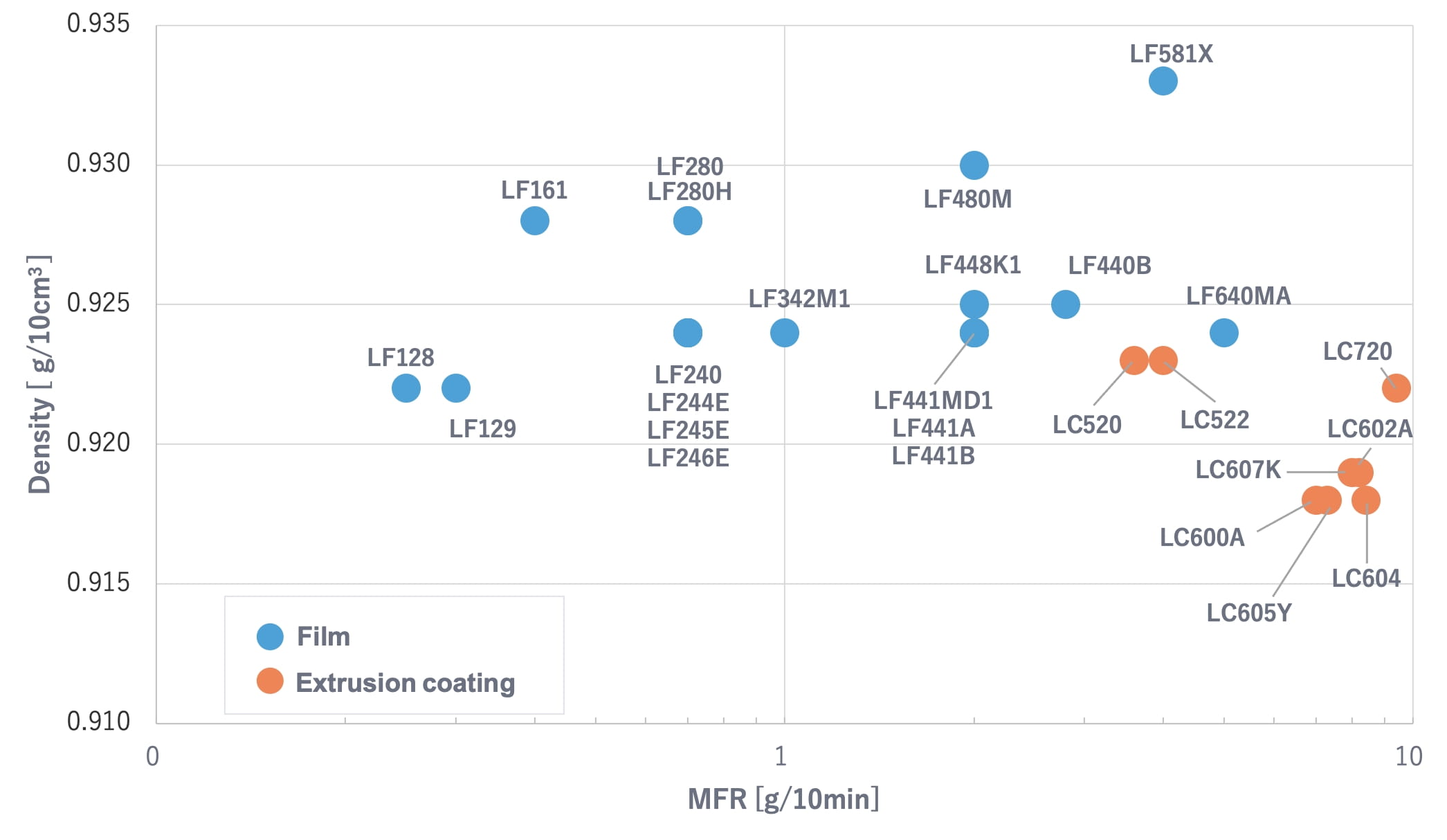

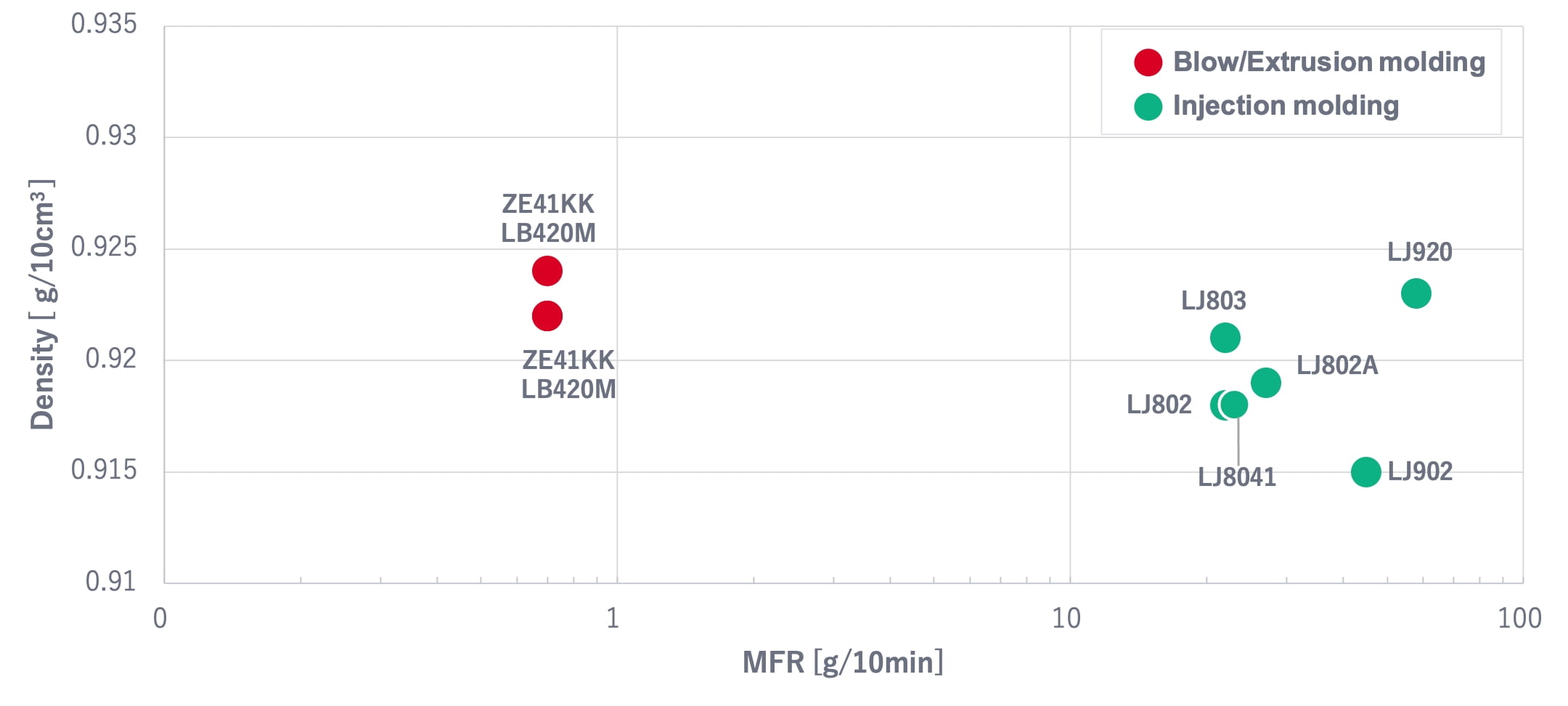

NOVATEC™ LD MFR/density profile

NOVATEC™ LD MFR/density profile