Features

m-PE KN has excellent flexibility and strength.

It is used for various application and fields, from food packaging to everyday items.

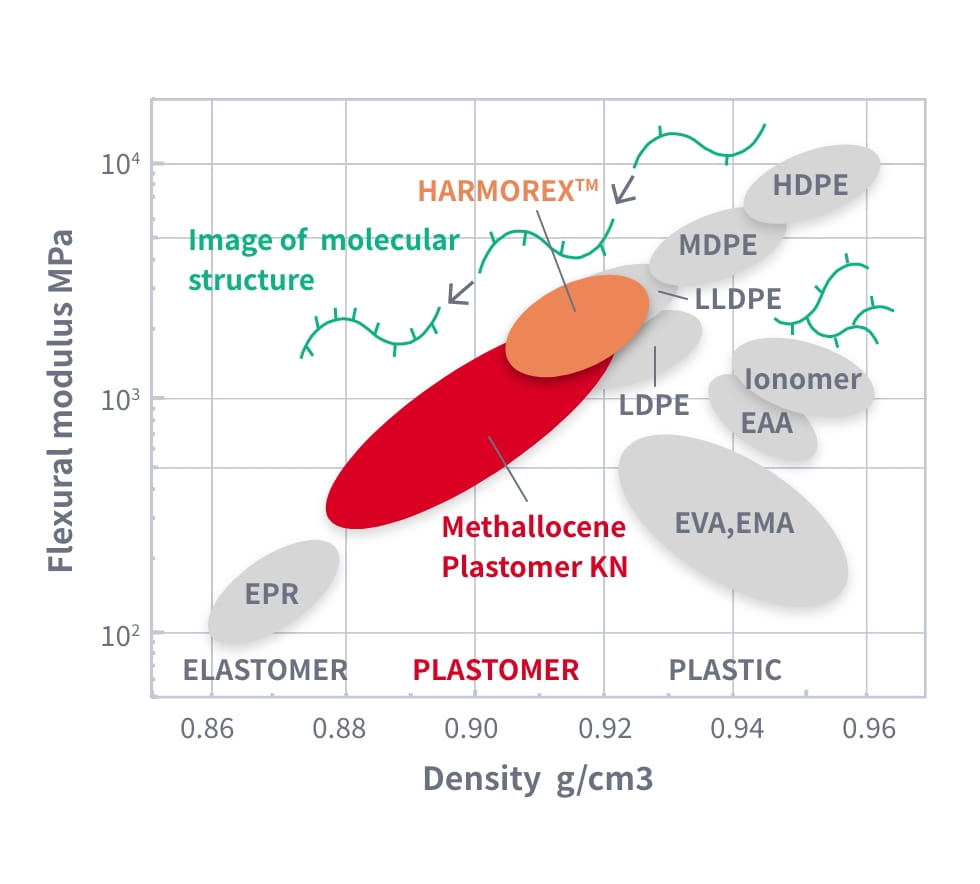

01High Flexibility

KN is an ethylene/alpha-olefin copolymer produced by high-pressure manufacturing technology using a metallocene catalyst. KN is a plastomer with uniform composition which has both the properties of plastic and elastomeric. It exhibits excellent flexibility and strength.

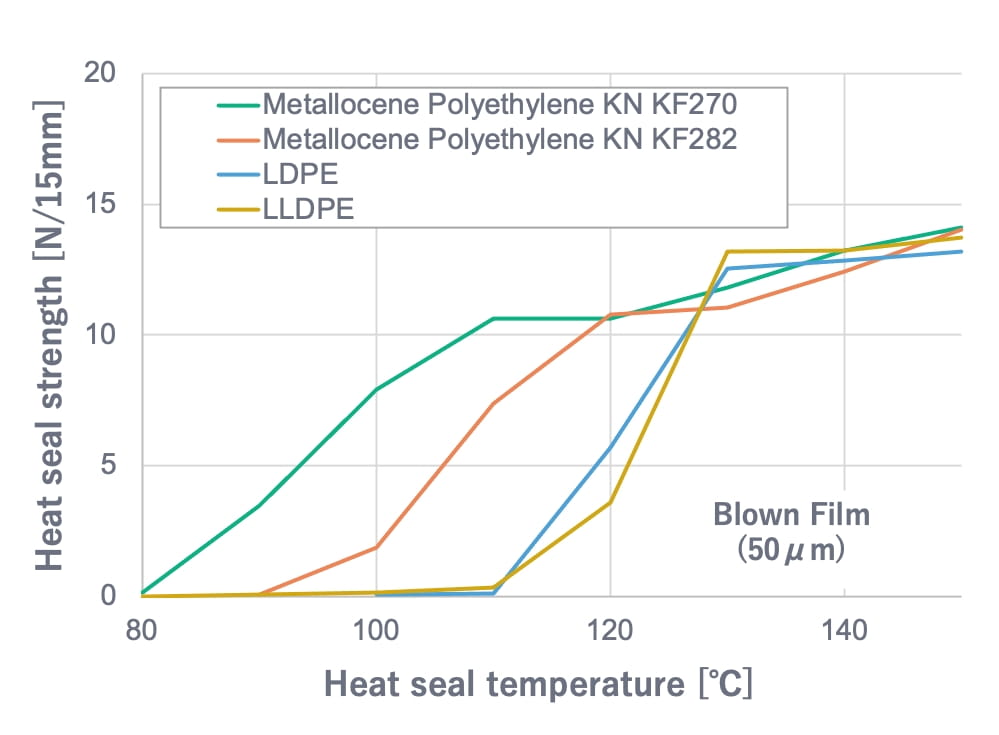

02Low Melting Point

Compared to conventional high-pressure low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE), it melts easily under heat, which means it can be sealed in a lower temperature (e.g., heat seal ability).

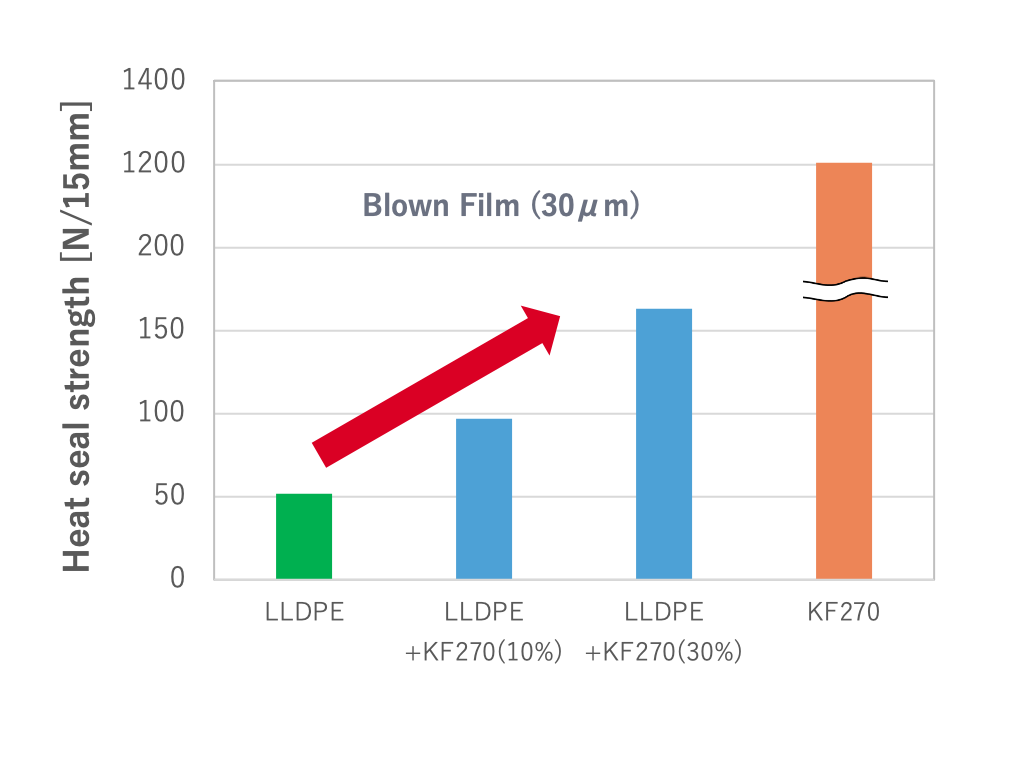

03High Strength

Compared to conventional high-pressure low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE), KN has excellent strength. Therefore, by blending KN with polyethylene or polypropylene, you can strengthen your products.

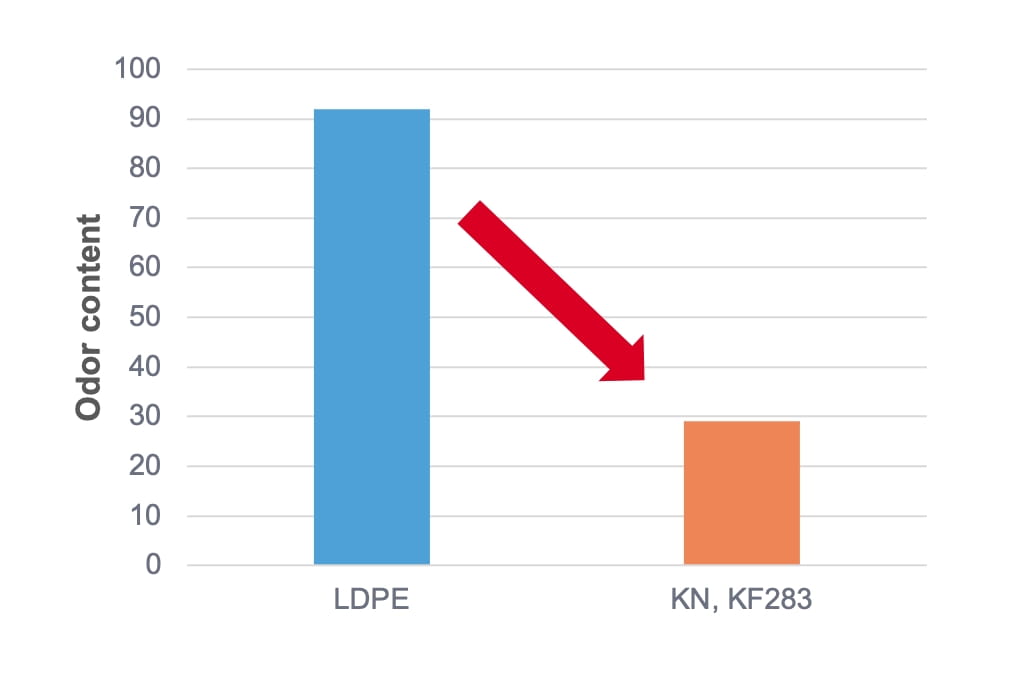

04Low Odor

Low odor is one of KNs specifications; this is because it does not have much volatile, which generally causes resin specific odors.

Application

KN is used in products which its specific features; high flexibility, low melting point, and high strength are needed.

Liquid-filled packaging bags

sealant film

bag-in-box

Chilled Containers

Agricultural Films

Line up / Download

Physical properties Metallocene Polyethylene KN™

- The information on this document shows typical properties and characteristics only and is intended as guide, not as specifications.

- Before using the product herein, the users should make their own determination of the suitability (quality, safety, legal, intellectual property rights etc.) of such products for the intended use.

- The product on this sheet may be not suitable for pharmaceutical or medical applications. When you use the product for such applications, please be sure to have a consultation with us in advance about your use.

- Please consult our company about applications in the food-contacting articles or durable goods.

- Please understand that this information provided herein might be changed without a previous notice.

*1 It is not suitable to use for fats, oils, and fatty foods at temperatures exceeding 100 °C.

*2 It is not suitable to use for all foods at temperatures above 100 °C.

*3 It is not suitable to use for fats, oils, or fatty foods, or when used with any food at temperatures above 100 °C.

Metallocene Polyethylene KN MFR/density profile