Features

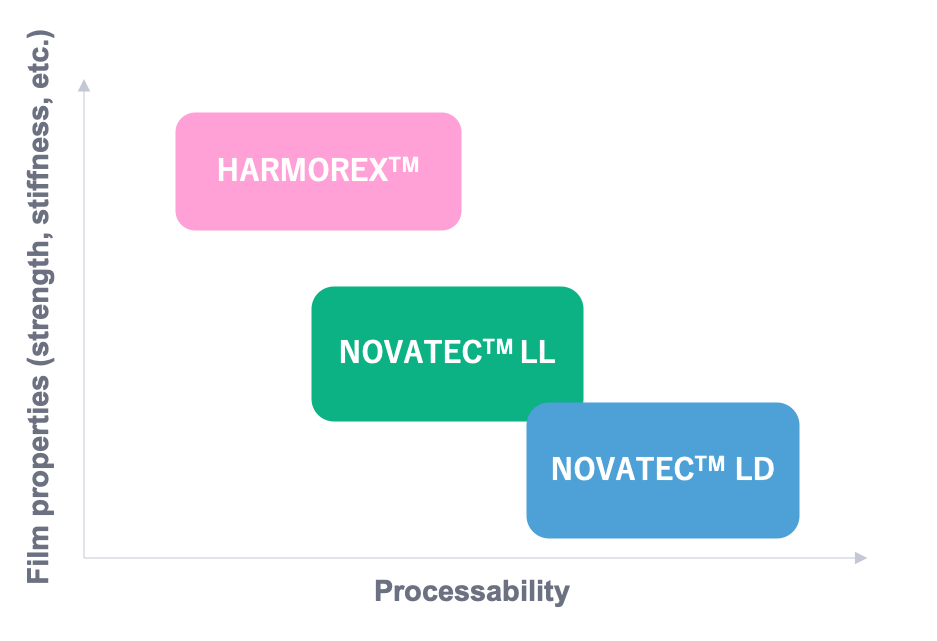

HARMOREX™ is a unique polyethylene made by using our gas phase process technology.

Its balance of physical properties and processability is excellent, and it also shows high cleanness.

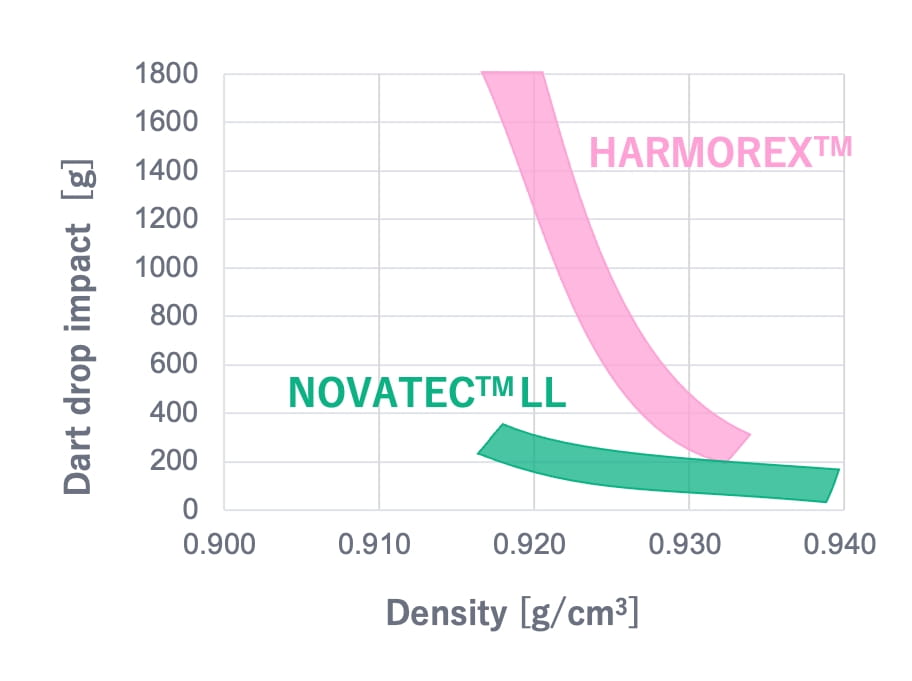

01High Strength

HARMOREX™ has a unique composition distribution and molecular weight distribution, which shows an exceptional balance of stiffness, strength, and impact resistance.

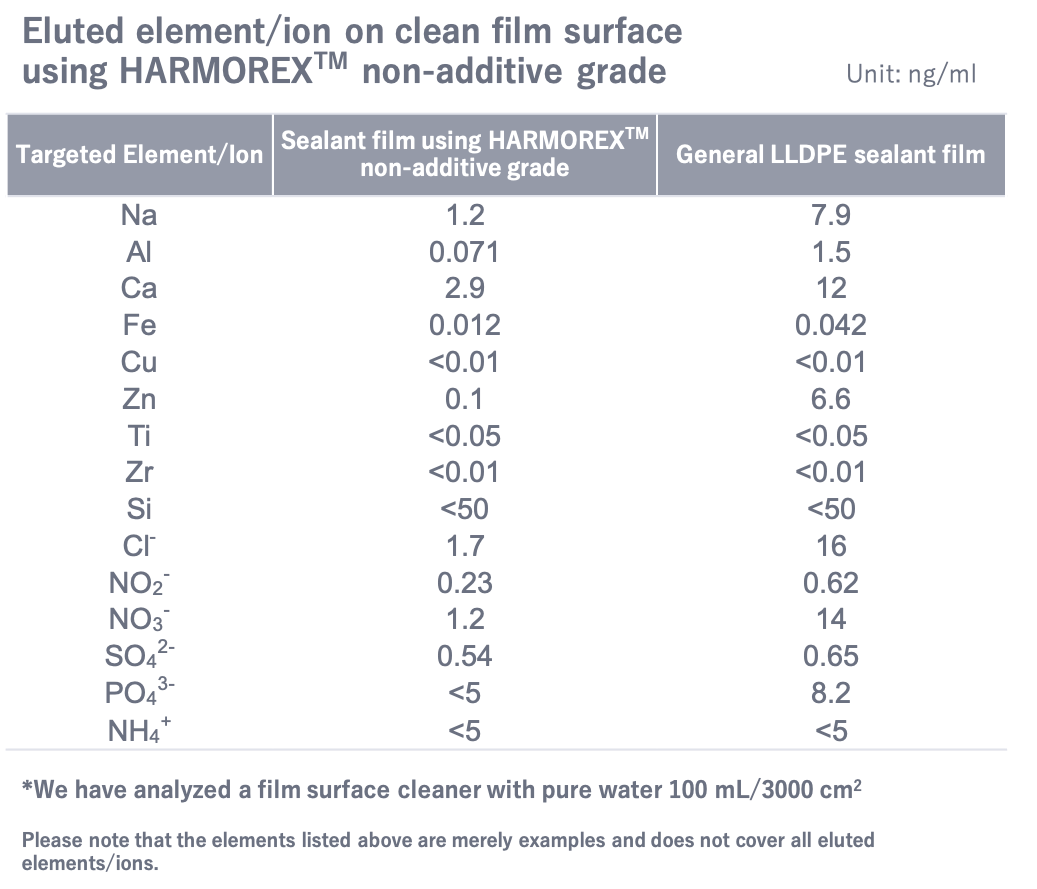

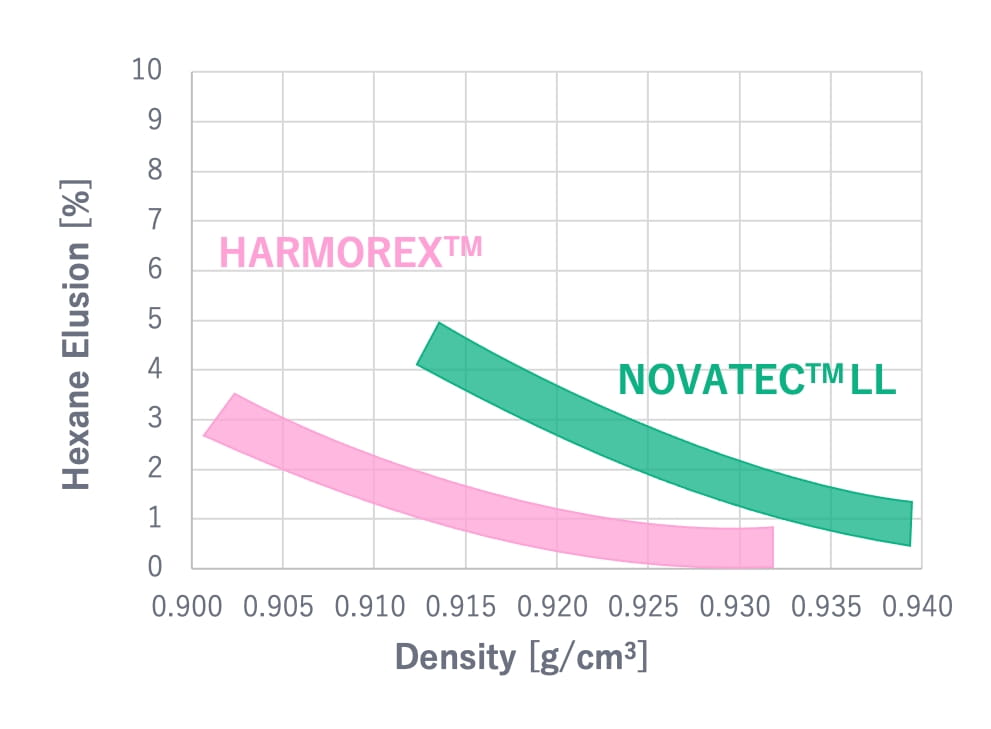

02Few eluted components

One of the characteristics of HARMOREX™ is its low amounts of eluted components. Compared to LLDPE using Ziegler catalysts, it has less n-hexane extractable components, so it is used in applications that require high cleanliness.

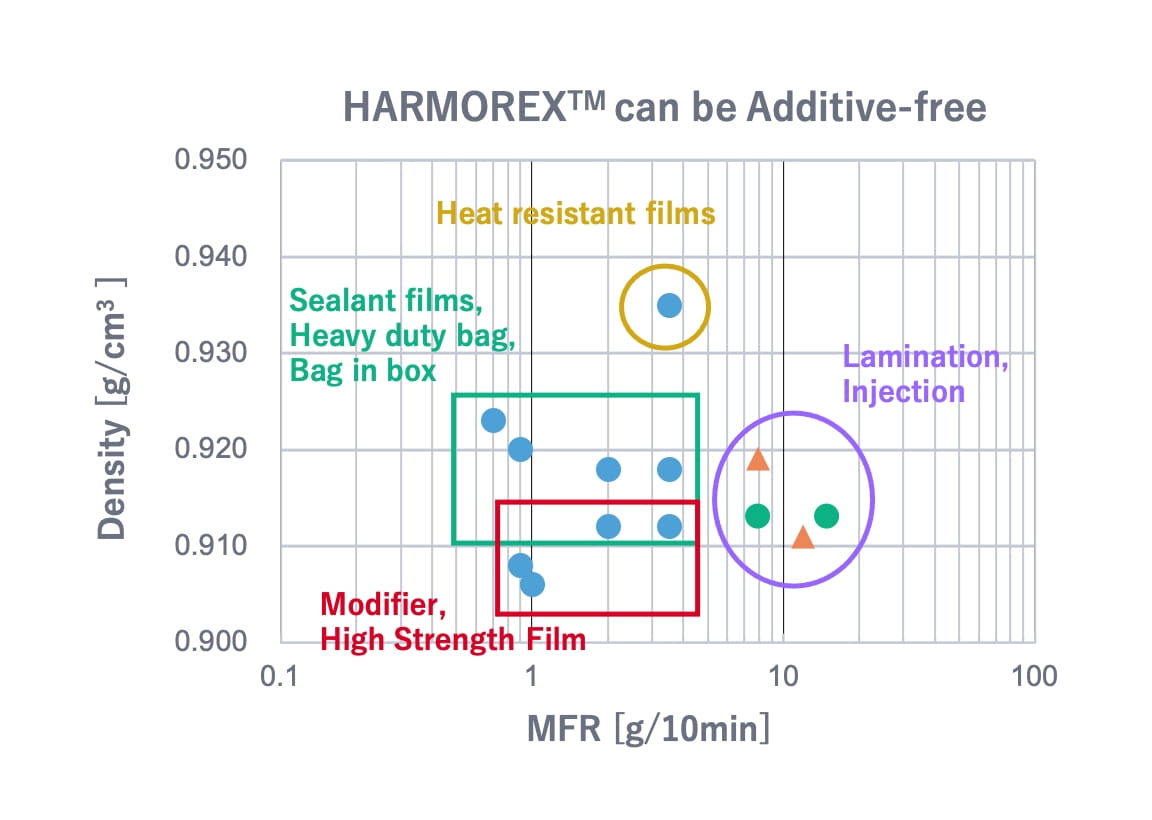

03Additive-Free

As HARMOREX™ can be produced without additives, it has the following characteristics.

- No bleeding of additives = No transfer of additives to the package contents.

- There is no transfer of odor or taste due to additives.

- No discoloration of the film caused by antioxidants.

- Applicable to various laws and regulations.

It is an ideal polyethylene for packaging materials for various contents such as food, dairy products, medical supplies, electronic parts and so on.

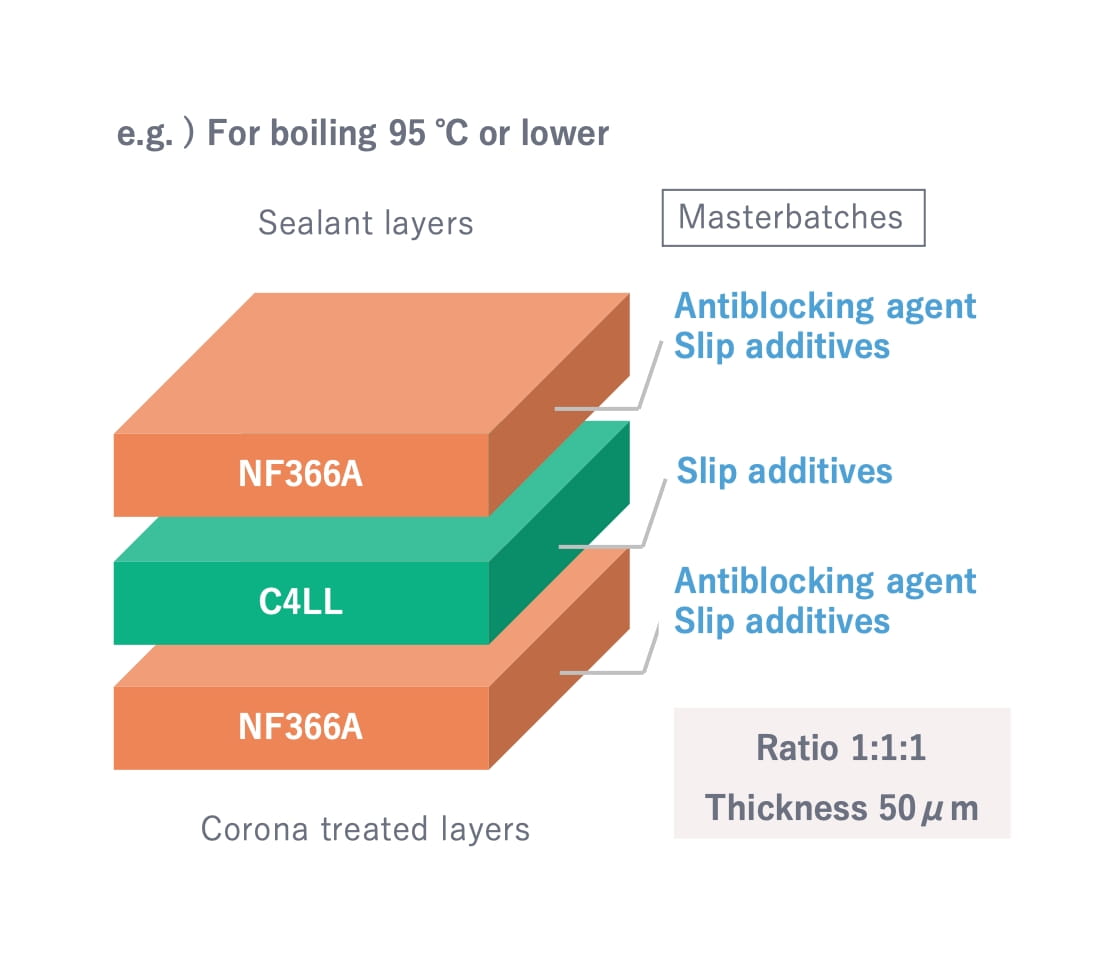

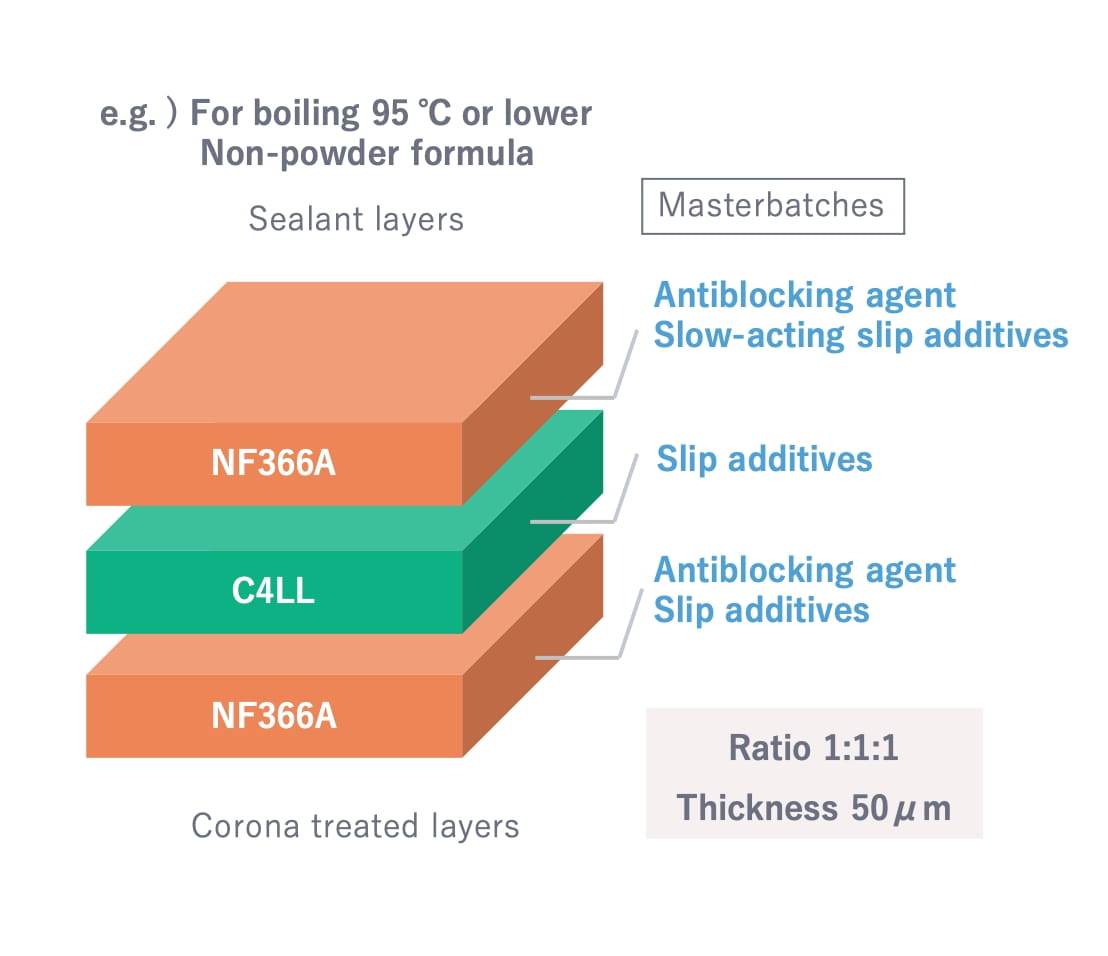

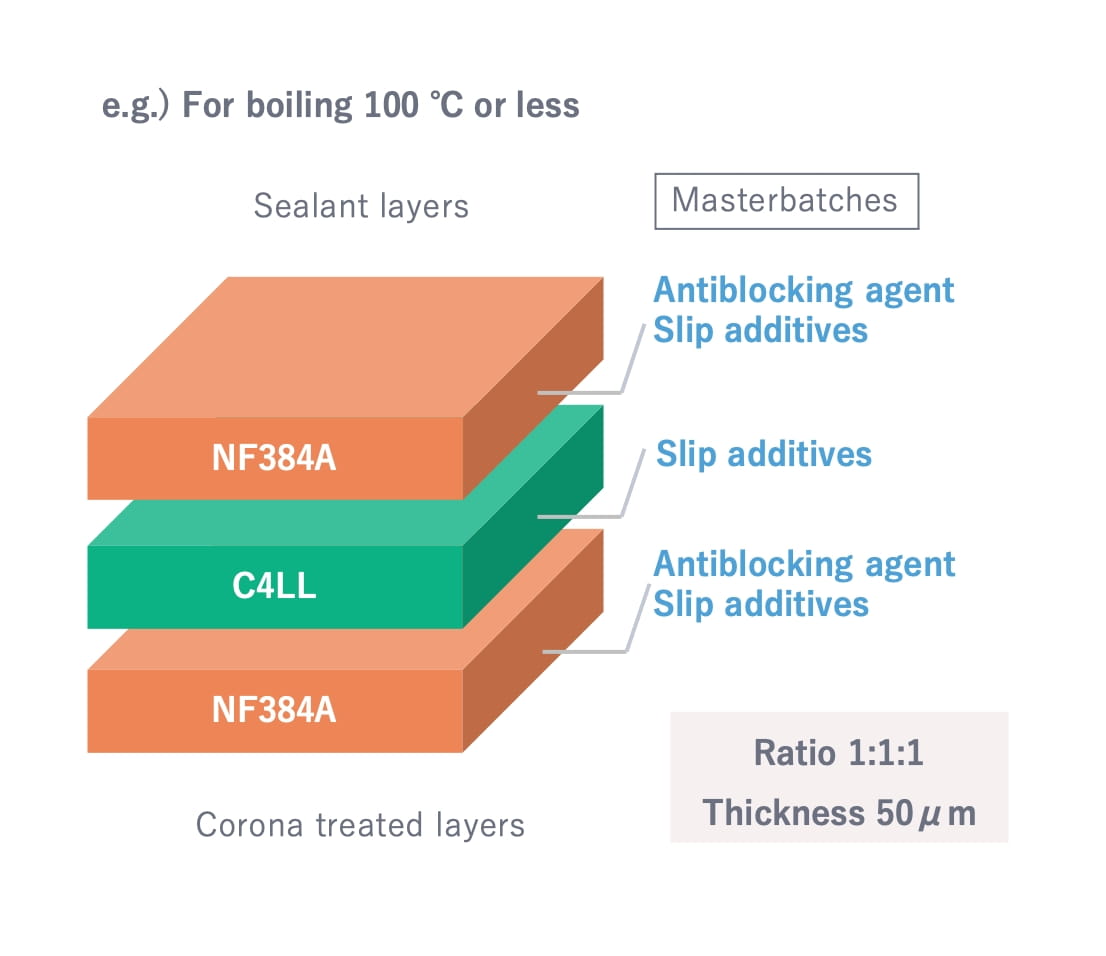

04Customizable

Customized formulations are available depending on your applications and film compositions. Using masterbatches* you can add different properties and also avoid the use of unnecessary additives. For further details, please contact us.

*Resins with a high-level additive. You must dilute them by a specific ratio when molding.

カスタマイズ例(Three-layer construction)

Application

HARMOREX is used for various applications such as films, clean packages, extrusion lamination, and so on.

Films

Additive-free Films

Heavy duty bags

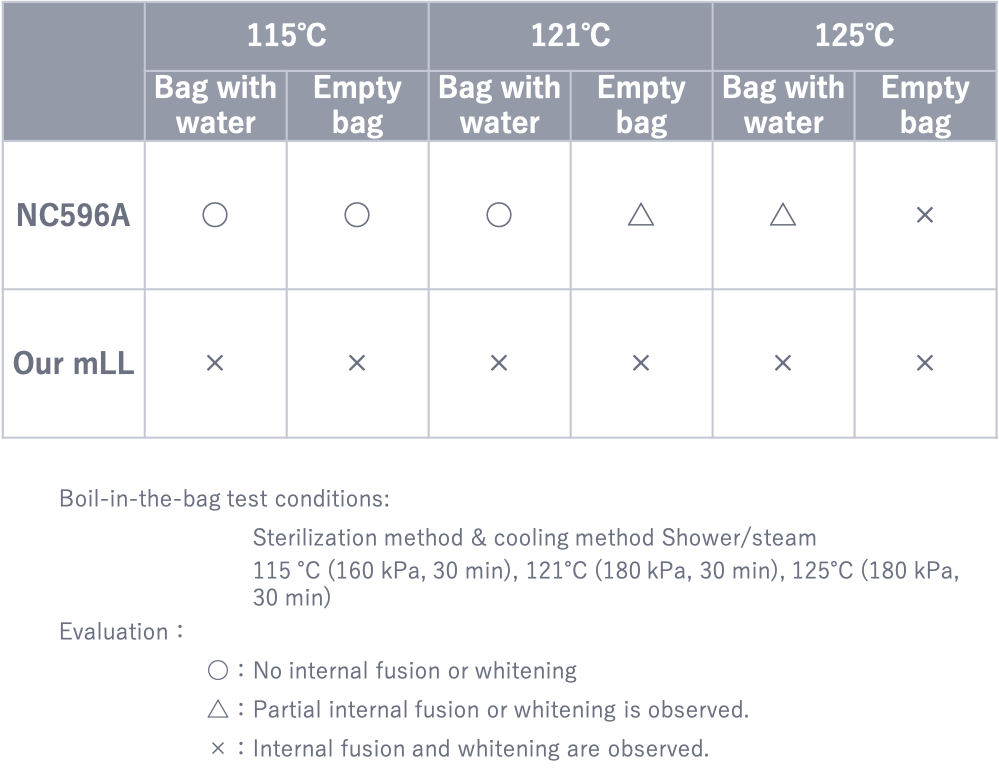

Heat resistant films

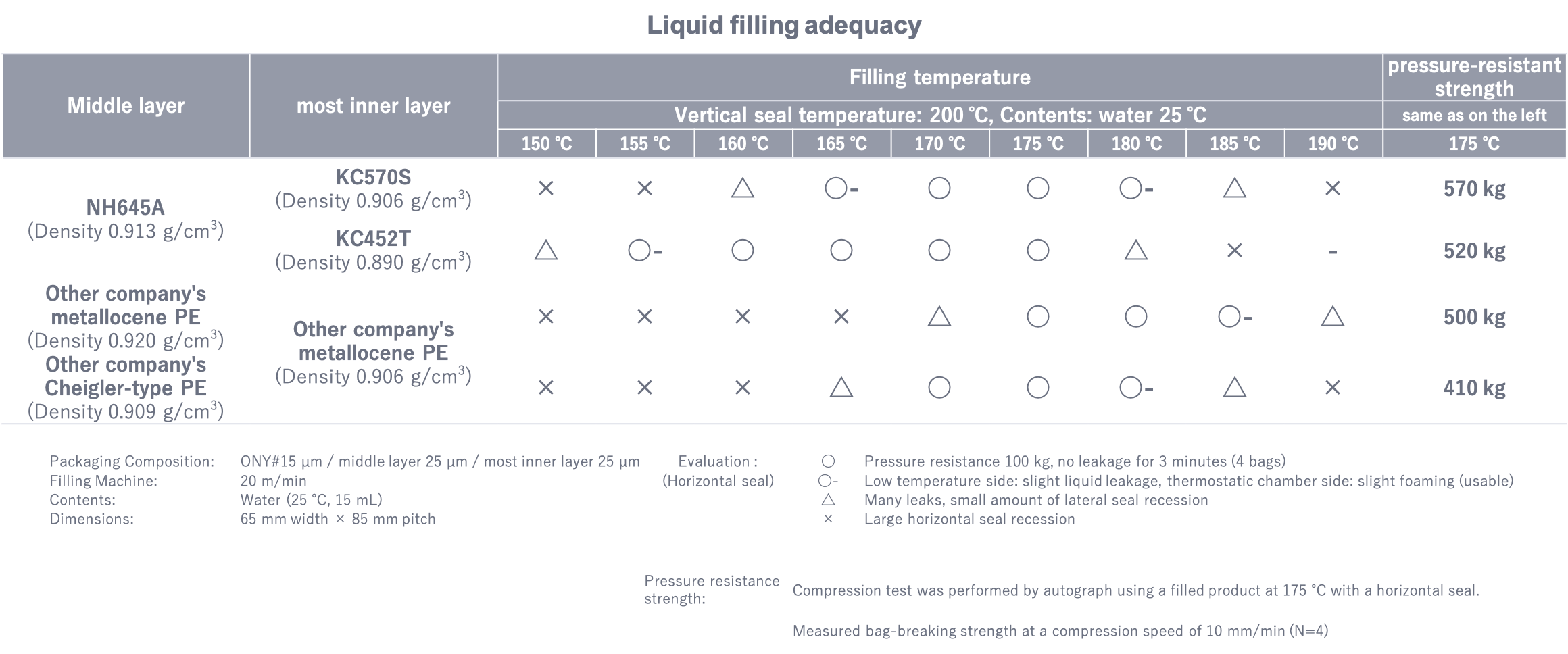

Liquid Small Bags

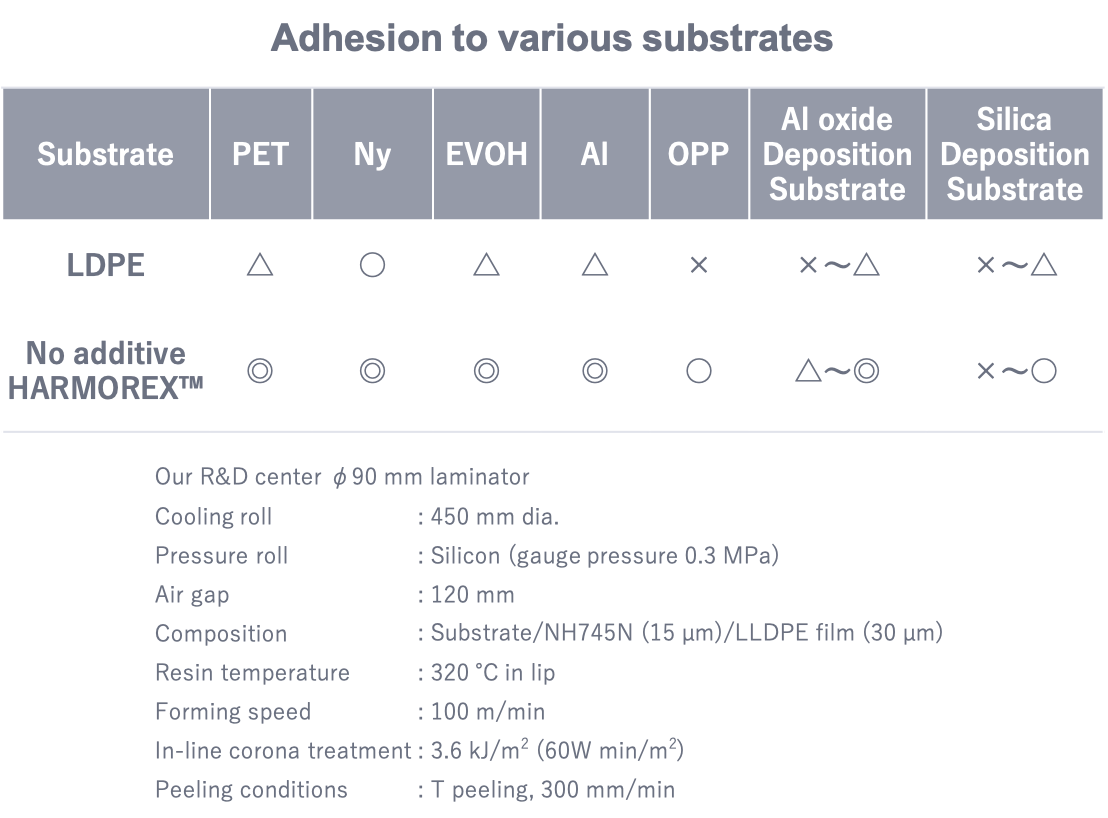

No Anchor Lamination

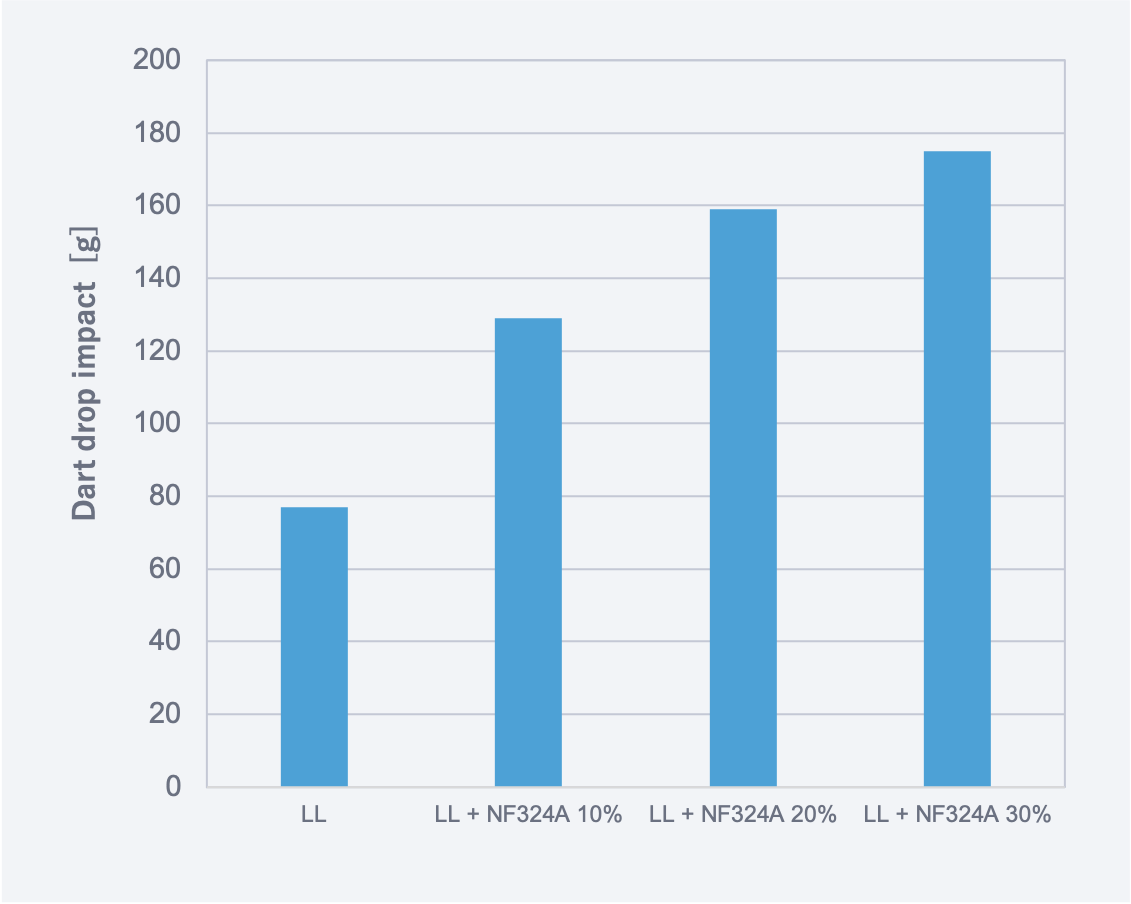

Resin Modifier

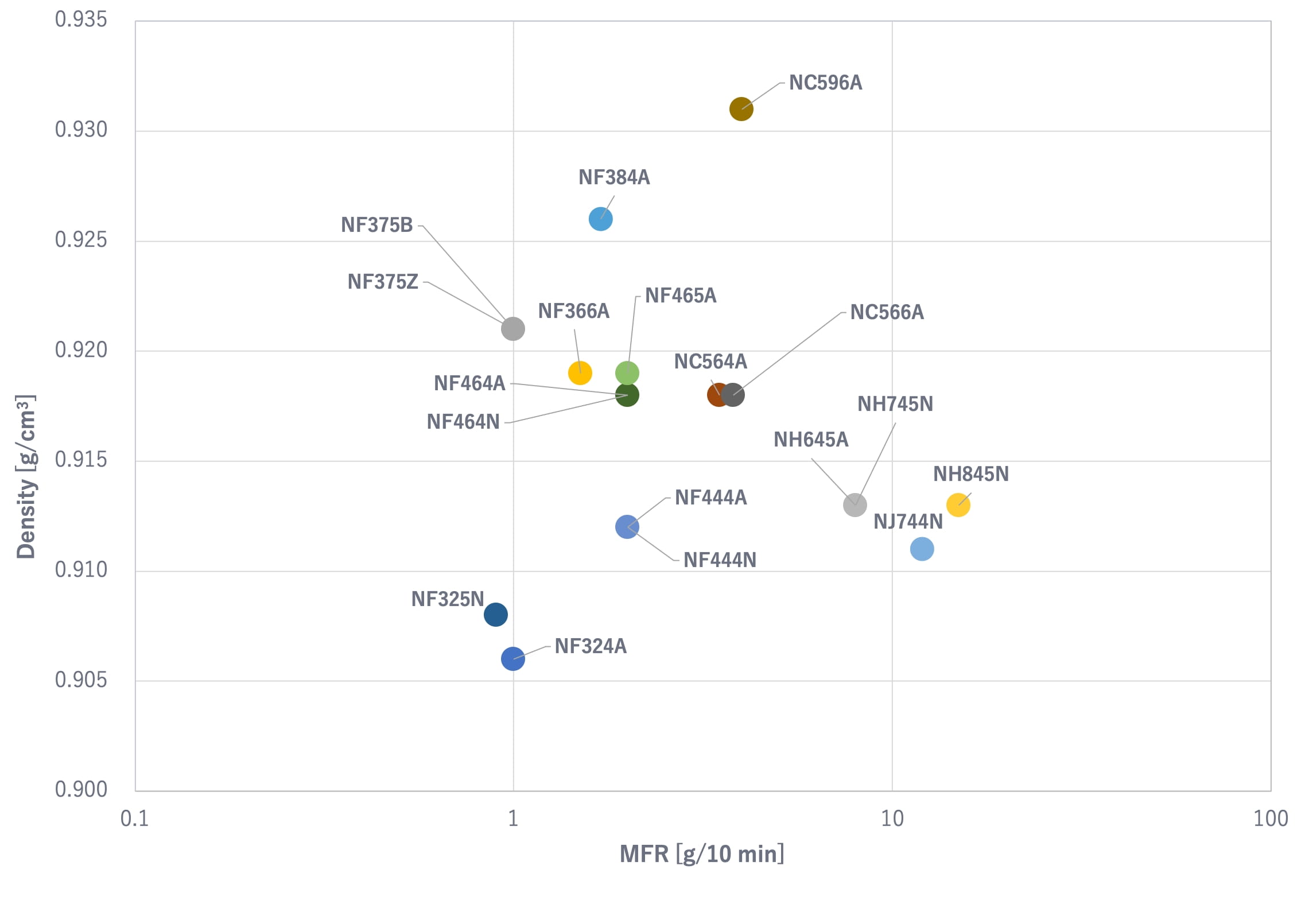

Line up / Download

Physical properties HARMOREX™

- The information on this document shows typical properties and characteristics only and is intended as guide, not as specifications.

- Before using the product herein, the users should make their own determination of the suitability (quality, safety, legal, intellectual property rights etc.) of such products for the intended use.

- The product on this sheet may be not suitable for pharmaceutical or medical applications. When you use the product for such applications, please be sure to have a consultation with us in advance about your use.

- Please consult our company about applications in the food-contacting articles or durable goods.

- Please understand that this information provided herein might be changed without a previous notice.

HARMOREX™ MFR/density profile