Features

NOVATEC™ LL is a linear low-density polyethylene(LLDPE). The density LLDPE is controlled by copolymerizing α-olefins as comonomers, and the type of branching varies depending on the type of the comonomer, resulting in the differences in strength properties.

01Various Grade Lineups

NOVATEC™ LL (linear low-density polyethylene) is mainly used for films for various applications; from food packaging to heavy duty bags such as rice bags. We have a wide variety of grades which can also be used for industrial parts, caps, lids, electric wires, tanks etc.

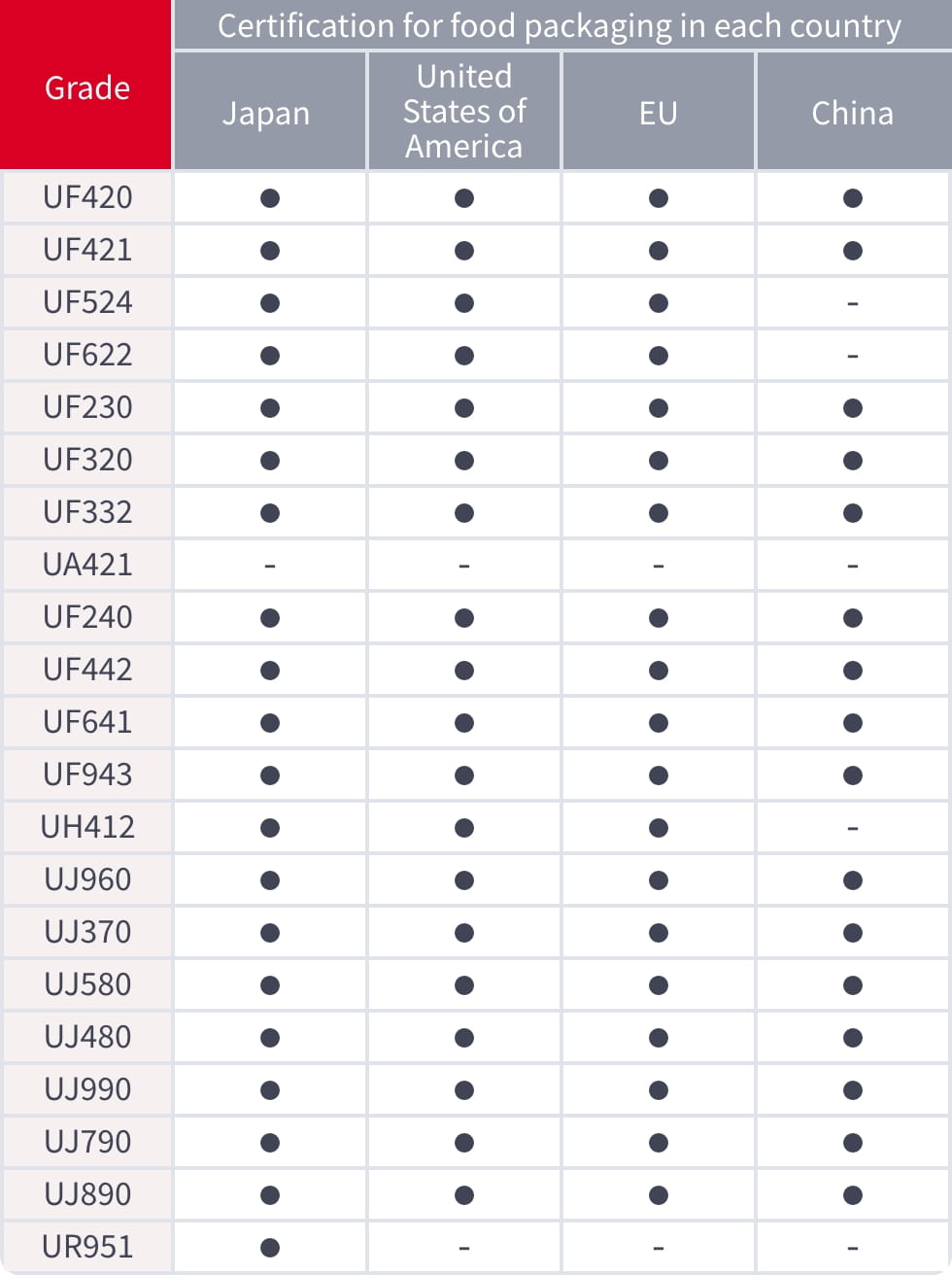

02Laws & Regulations

We have grades which meets national laws and regulations.

| Japan: | Food Sanitation Act Notification no.370, JCII(Japan Chemical Innovation and Inspection Institute)voluntary standards for food utensils, containers and packaging materials |

|---|---|

| US: | Code of Federal Regulations Title 21 |

| EU: | Regulation(EU) 10/2011 |

| PRC: | GB4806.6-2016, GB9685-2016, Public notice of NHC |

[Notes]

This does not give any guarantee to the products itself made from our polyethylene.

Please note that contents reported here are not guaranteed to be always up to date. Laws and registrations noted here may be changed in the future.

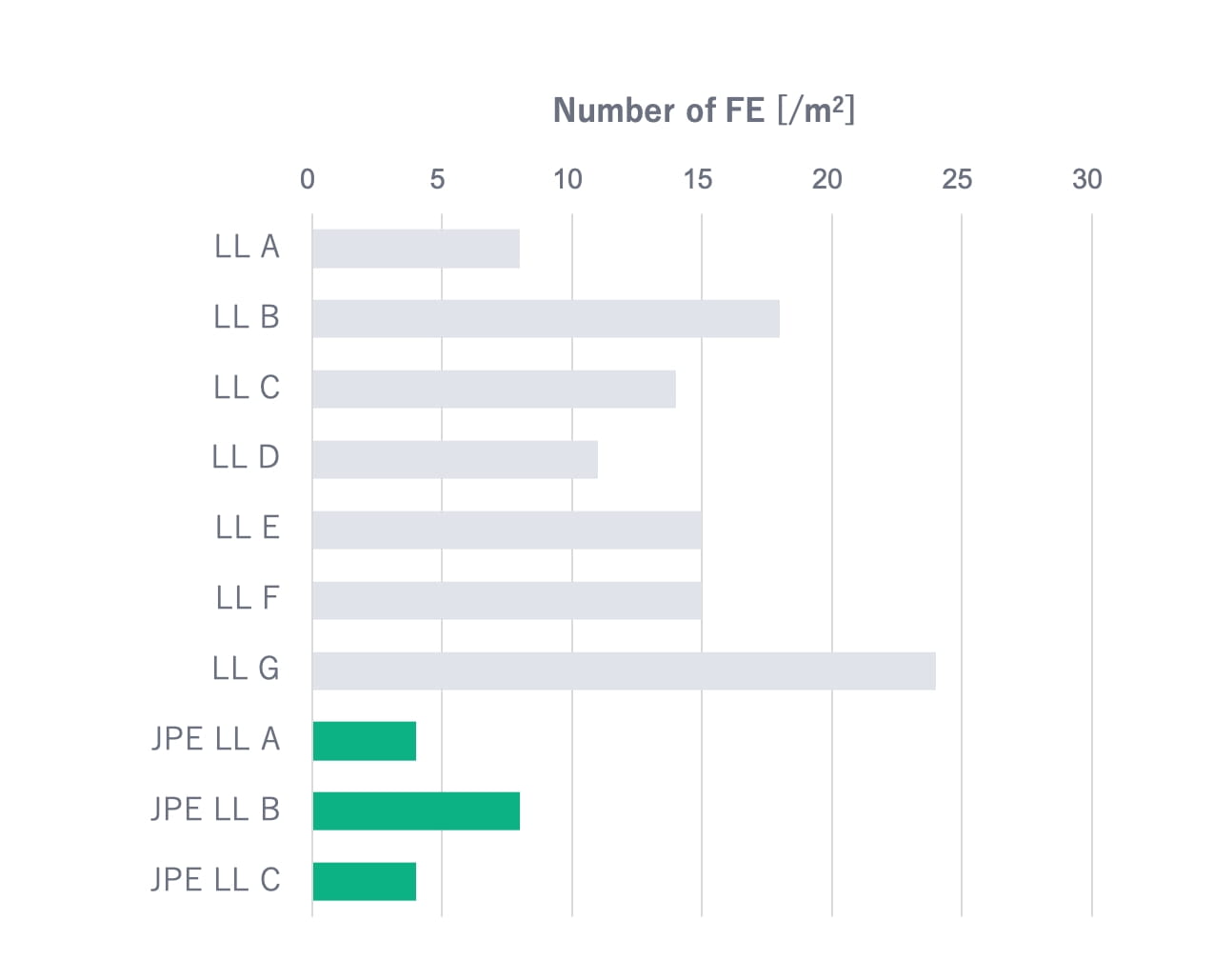

03Stable Quality & Supply

We provide polyethylene using processing technology and quality control based on many years of factory management experience.

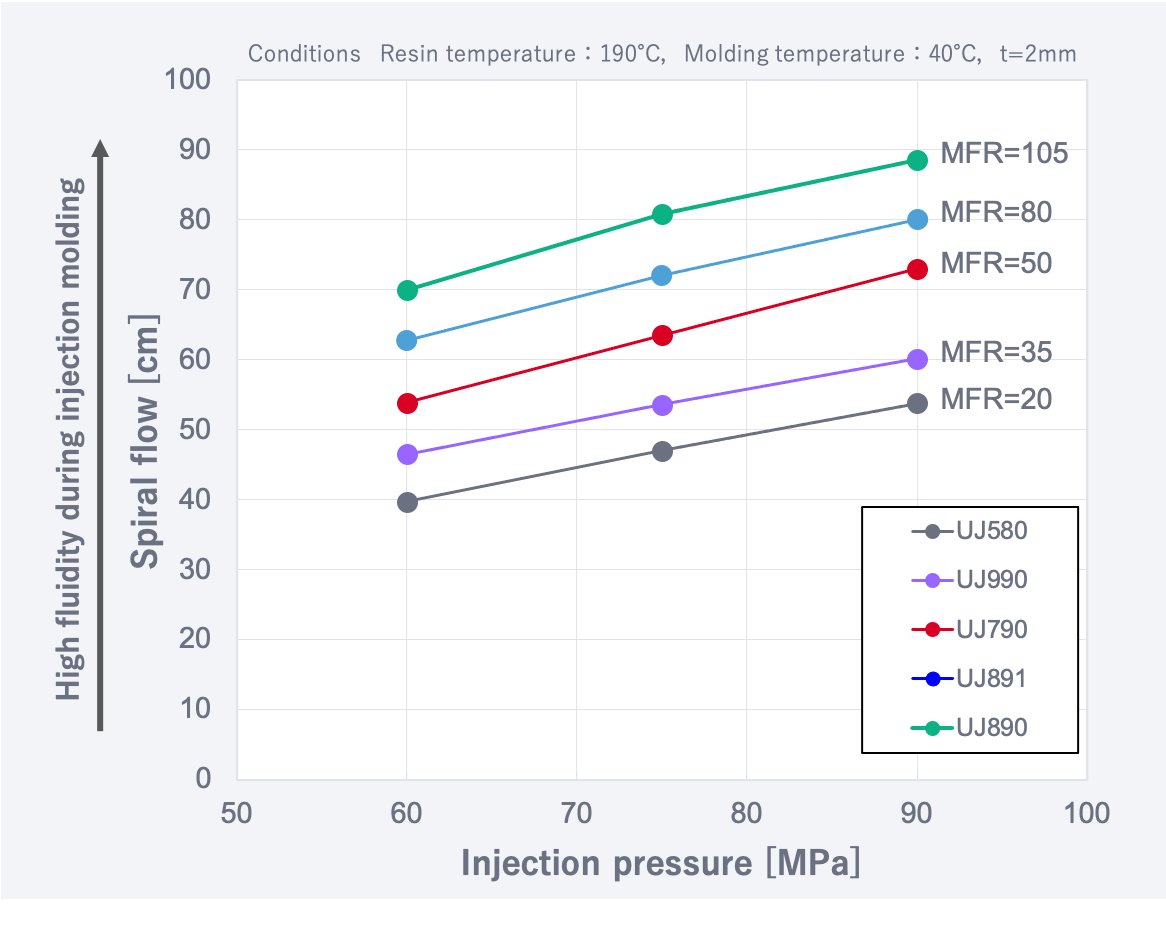

04Designed for your molding process

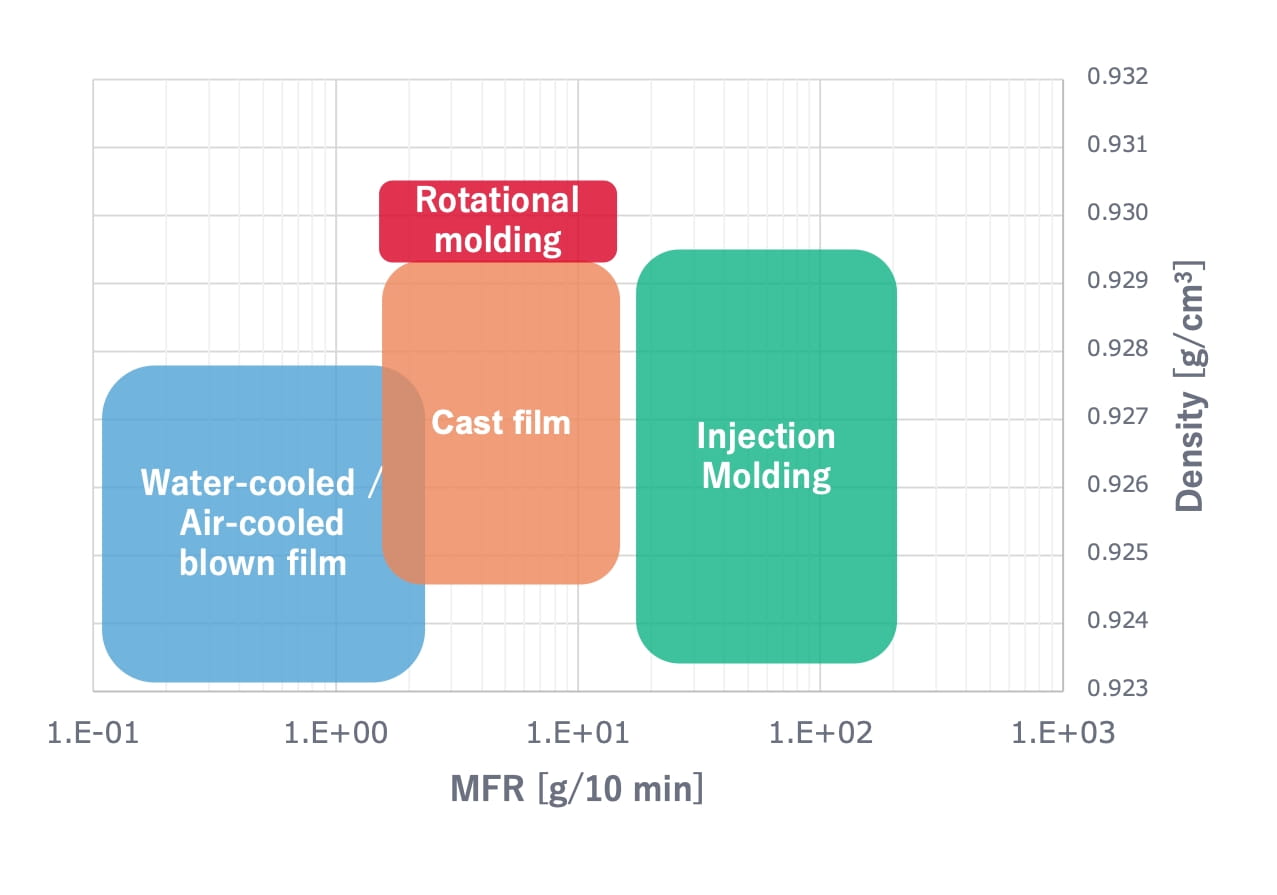

We have grades suitable for air-cooled blown film, water-cooled blown film, cast film, injection molding, extrusion molding, etc.

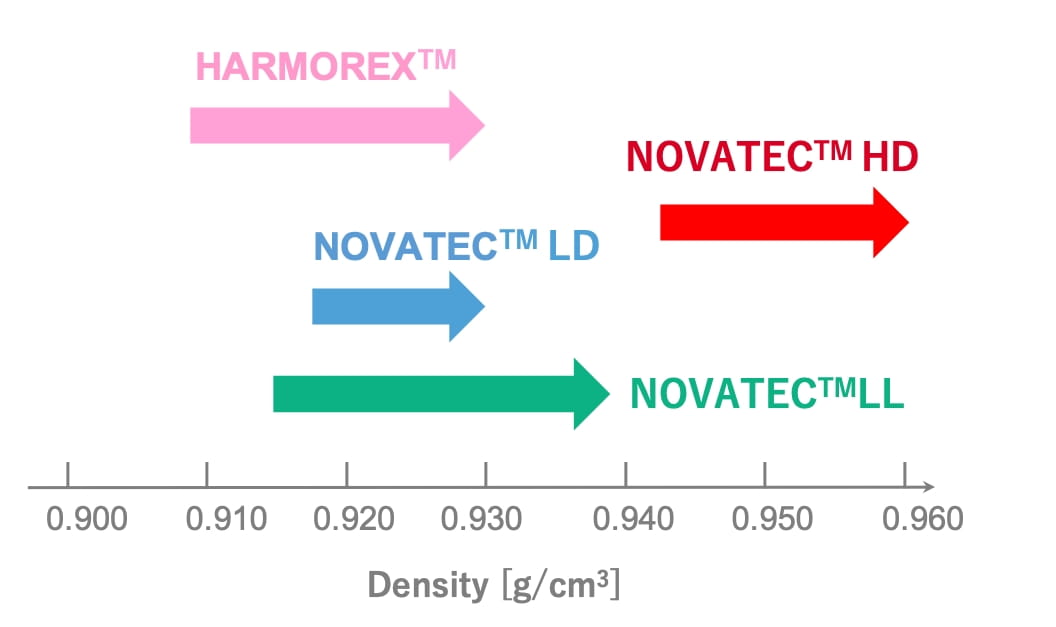

05Suitable for all types of packages

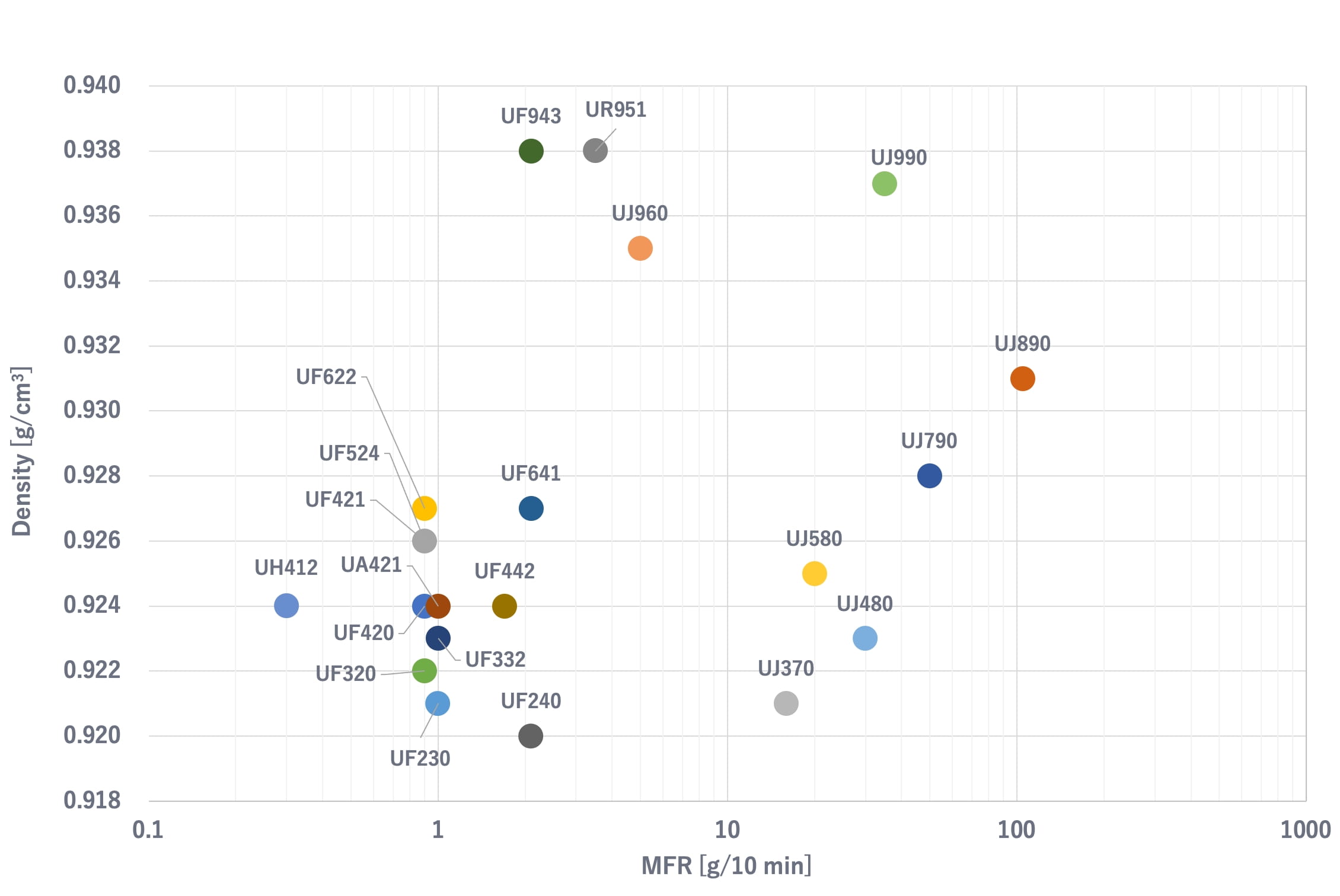

A wide range of film grades are available, from low density grades which has high flexibility and high impact strength to high density grades which has high stiffness and good heat resistance.

06Designed for various applications

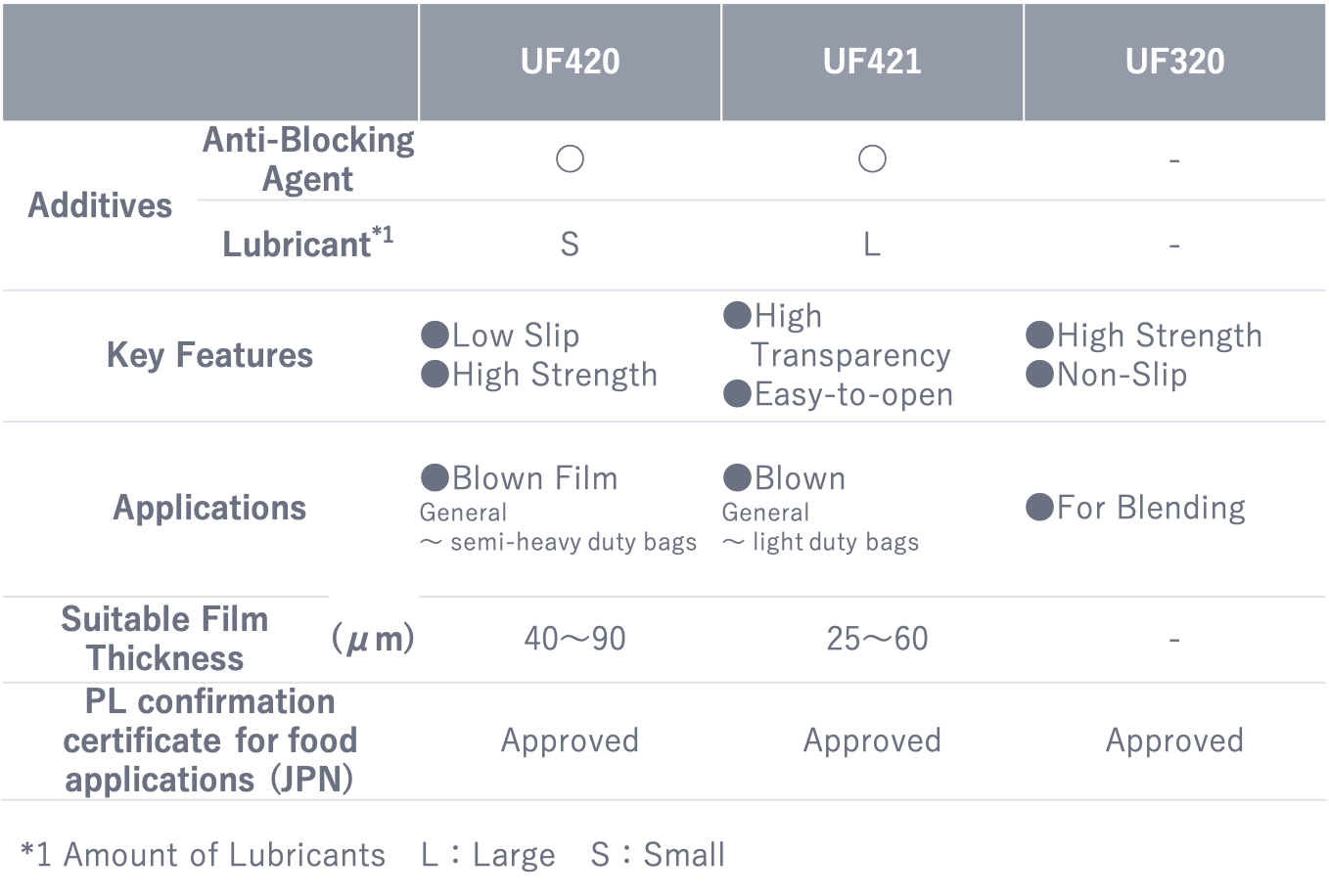

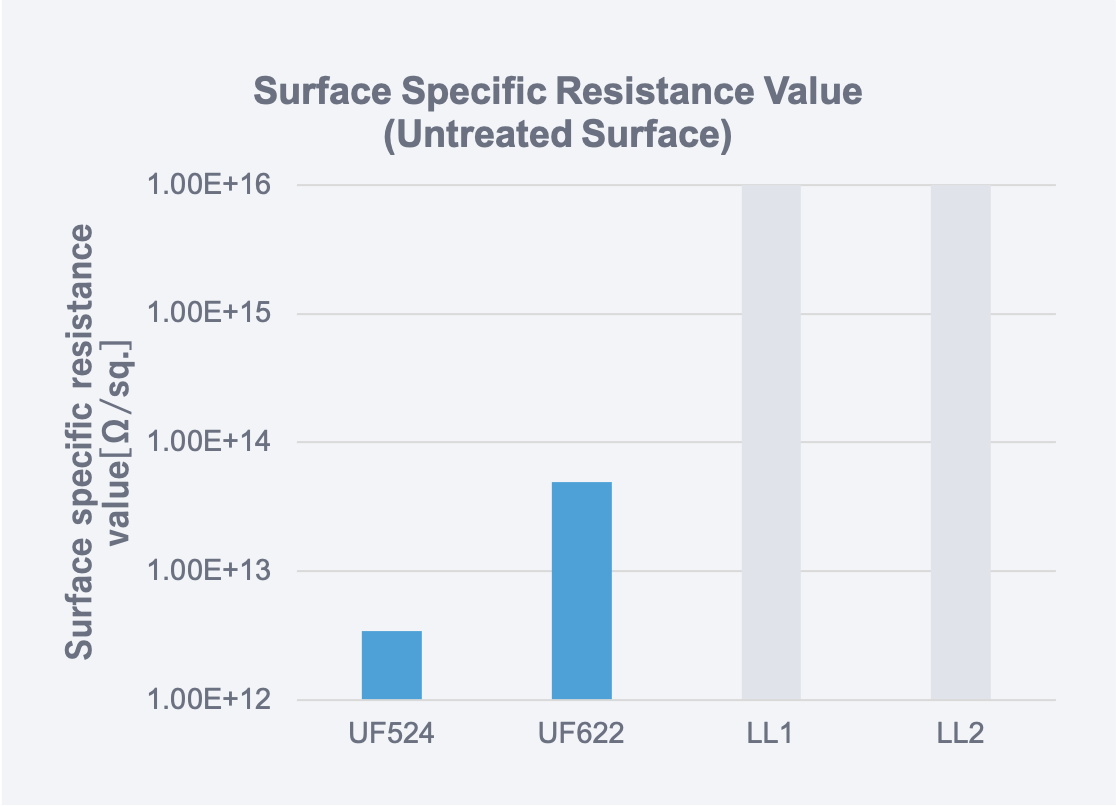

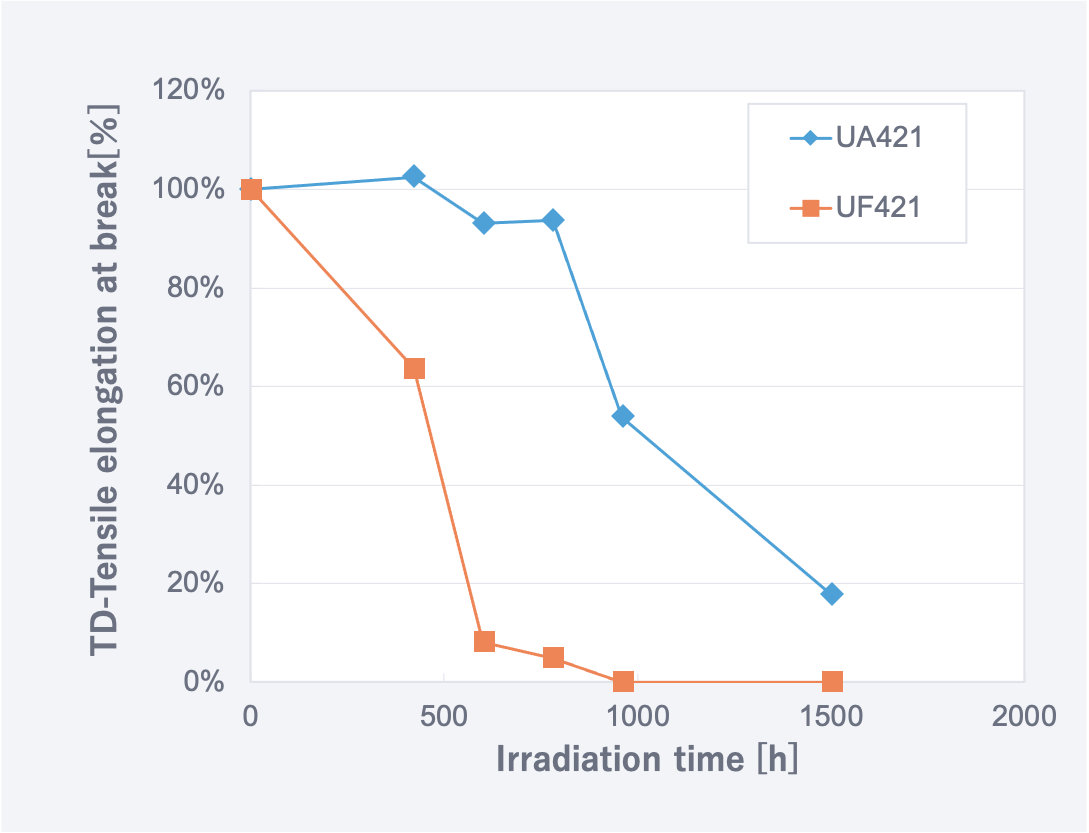

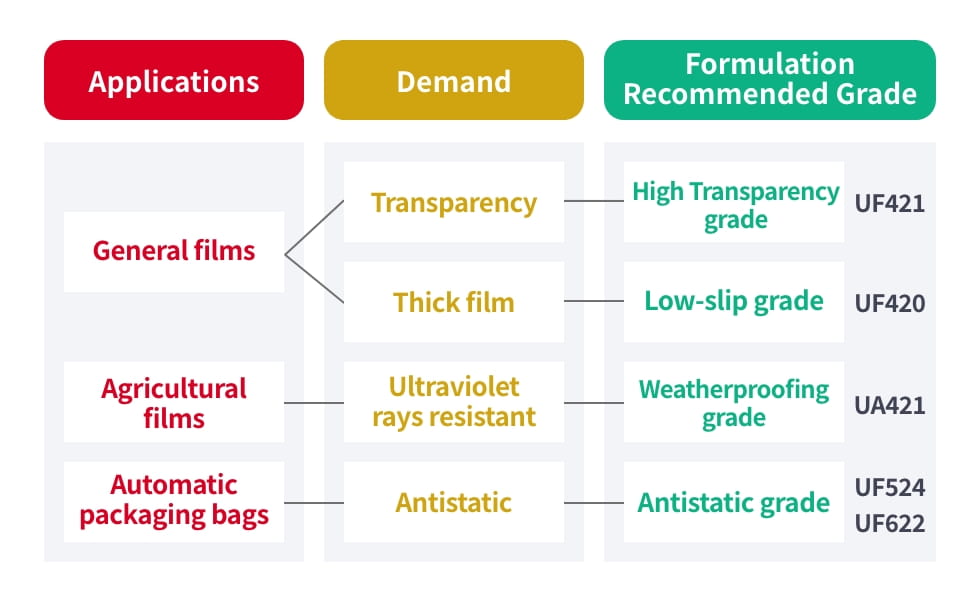

We have a wide variety of grades that contain the necessary additives depending on your application. You can use resins without blending masterbatches (resins with additives dispersed in high concentration). Please contact us for further details.

Application

NOVATEC LL is a linear low-density polyethylene used for various applications; from films to injection products

Films

Auto package bags

Agricultural Films

Injection

Thin package lids

Line up / Download

Physical properties NOVATEC™ LL

- The information on this document shows typical properties and characteristics only and is intended as guide, not as specifica tions.

- Before using the product herein, the users should make their own determination of the suitability (quality, safety, legal, in tellectual property rights etc.) of such products for the intended use.

- The product on this sheet may be not suitable for pharmaceutical or medical applications. When you use the product for such a pplications, please be sure to have a consultation with us in advance

- about your use.

- Please consult our company about applications in the food-contacting articles or durable goods.

- Please understand that this information provided herein might be changed without a previous notice.

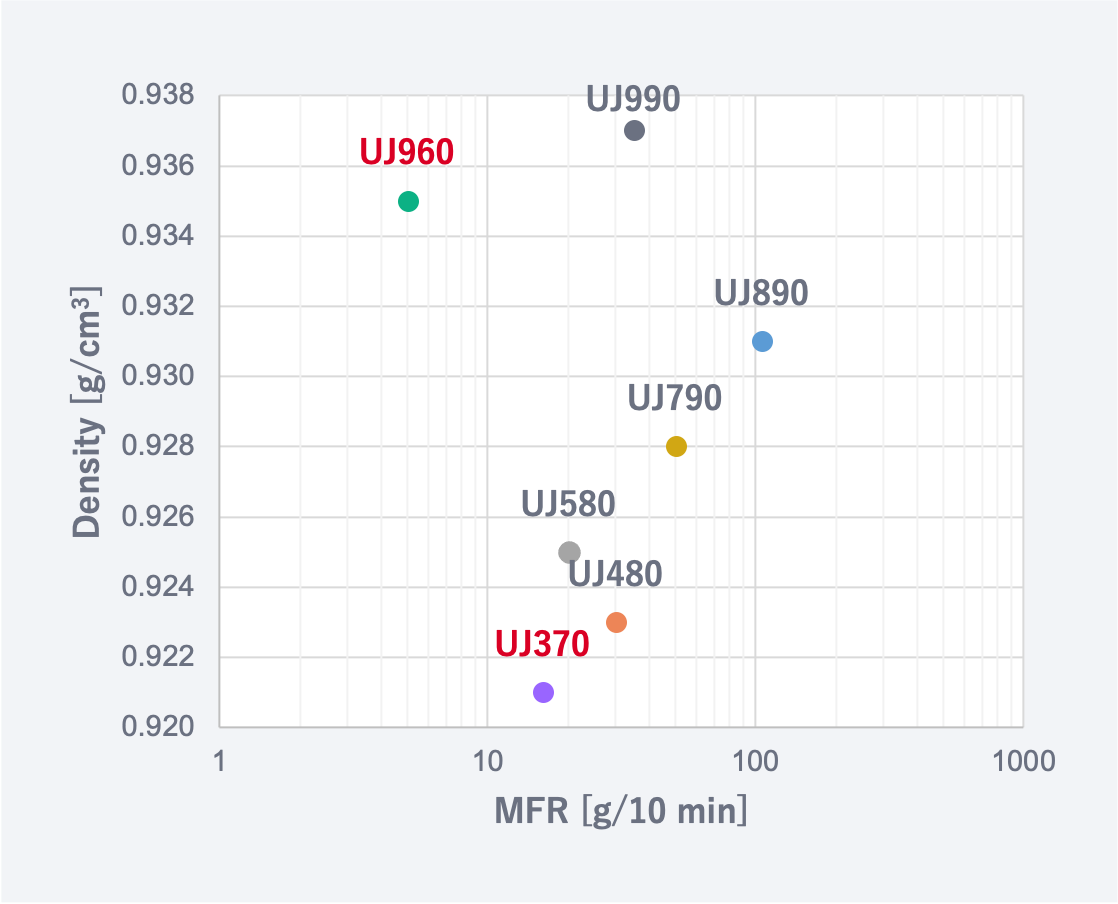

NOVATEC™LL MFR/density profile