Japan Polychem Group‘s proprietary catalyst technology has newly created an ethylene ionomer with a linear structure.It has very high crystallinity, high melting point, and high strength like no other conventional PE.

Although this is still under development, here we will introduce some of its significant performance and new values that Ionomer can offer.

Development Concept

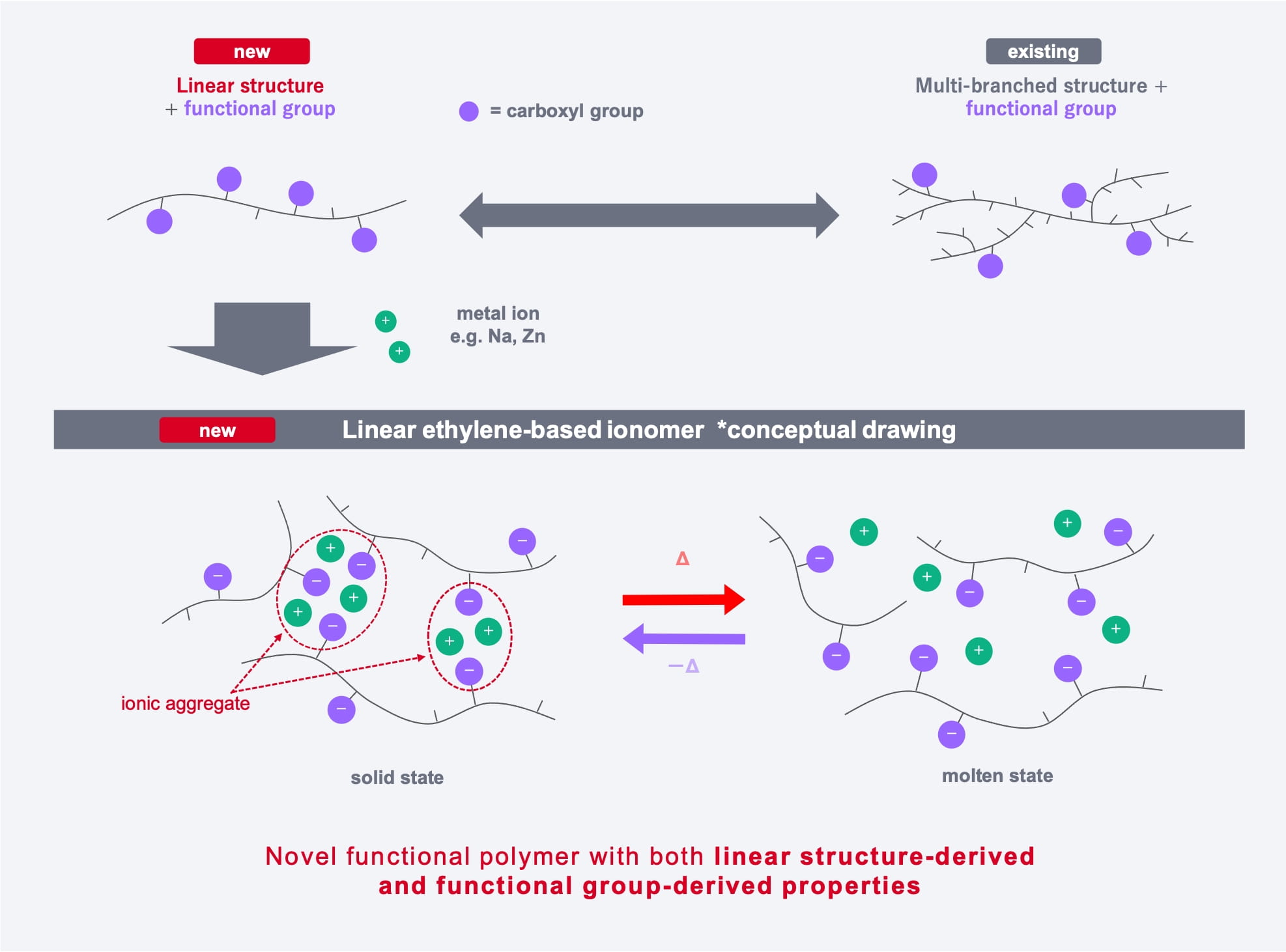

What is an ionomer?

Ionomers are a type of ionic polymer that forms pseudo cross-linking points with ionic aggregates by introducing ionic functional groups into a part of the molecular chain. In the solid state, ionic aggregates act as pseudo cross-linking points, enabling ionomers to improve mechanical performance and develop new functions while retaining some of the properties of the original copolymer. On the other hand, ionomers exhibit thermoplasticity despite their network structure, making them suitable for various molding processes such as extrusion and injection molding.

Linear ethylene ionomer developed by Japan Polyethylene Corporation has excellent material properties derived both from the linear structure and the ionomer.

Intended use

Taking advantage of the excellent properties of linear ethylene ionomers, we are expecting this to be used in various applications and fields.

To tune our grades to meet the markets’ needs, we are now doing application development and market research.

Film and Sheet

Food packaging films with good sticking resistance, low-temperature heat sealability, and gloss

Protection sheet with scratch resistance and high transparency

Fiber

Light and strong fiber by melt spinning molding

Injection molded and blow molded products

Containers and components with excellent transparency and mechanical properties can be made by injection molding and injection stretch-blow molding

3D Printing

Excellent three-dimensional moldability. The molded product will both have moderate flexibility and strength.

Heterogeneous material composite

Dissimilar material composites (steel wire coating, laminated glass interlayer film, etc.) utilizing adhesion to metal, glass, etc.

Water-based Coating

Coating agent for building materials, excellent in abrasion resistance, scratch resistance, and water and chemical resistance

Coating agent for food wrapping paper, information recording paper, etc., utilizing heat-sealing characteristics and water resistance

Aerospace

Various applications in the aerospace and aviation fields utilizing abrasion resistance, scratch resistance, light weight, etc.

Sports

Various applications in the sports field utilizing abrasion resistance, resilience, and water resistance (hydrolysis resistance)

Energy

Various applications in the energy field, such as solar cell encapsulants, utilizing transparency and adhesiveness